In the modern packaging industry, aluminum-plastic caps, as a high-end sealing material that combines excellent sealing performance with convenience, are widely used in pharmaceuticals, health products, beverages, and cosmetics. For many buyers and manufacturers, a thorough understanding of the structure and performance of aluminum-plastic caps is crucial to ensuring product packaging quality.

Content

I. What are Aluminum-Plastic Caps?

Aluminum-plastic caps, as the name suggests, are a new type of packaging cap made by combining aluminum alloy foil and plastic support components through a special process.

Compared to traditional all-aluminum or all-plastic caps, aluminum-plastic caps combine the advantages of both:

- High sealing performance: Utilizing the excellent barrier properties of aluminum, they effectively prevent the intrusion of oxygen and moisture.

- Easy to open: The design of the plastic components allows consumers to easily open the cap without complicated tools.

- Safety: They have good anti-counterfeiting features and a one-time opening mark, ensuring that the product cannot be refilled.

In the pharmaceutical industry, especially for antibiotics, powder injections, and large-volume parenteral solutions, aluminum-plastic caps have become a standard packaging configuration that meets GMP requirements.

II. Main Structural Components of an Aluminum-Plastic Cap

A high-quality aluminum-plastic cap is not simply a matter of stacking components, but rather a precision assembly of three core parts:

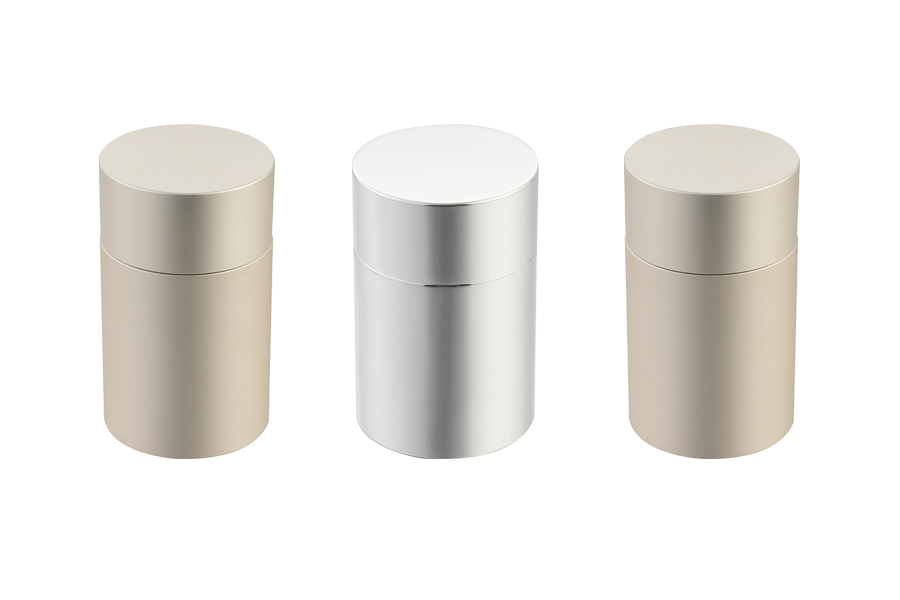

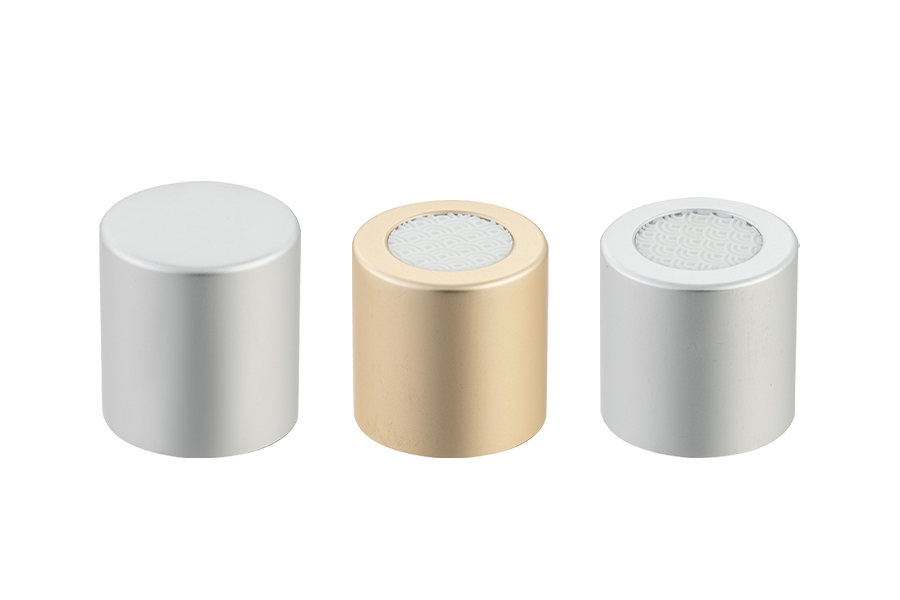

1. Aluminum Alloy Cap Body (Aluminum Components)

This is the skeleton of the aluminum-plastic cap, typically made of high-quality aluminum alloy foil such as 8011-H14/H16.

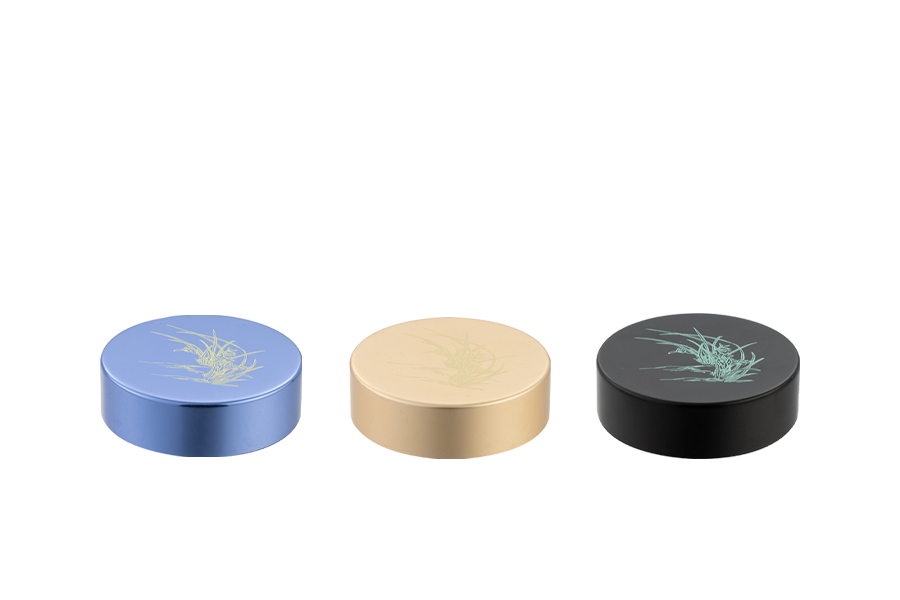

- Surface Treatment: Painted or anodized, it not only enhances aesthetics but also improves oxidation resistance.

- Function: Provides stable physical support, and through pleating by a sealing machine, ensures the cap tightly seals onto the bottle neck flange.

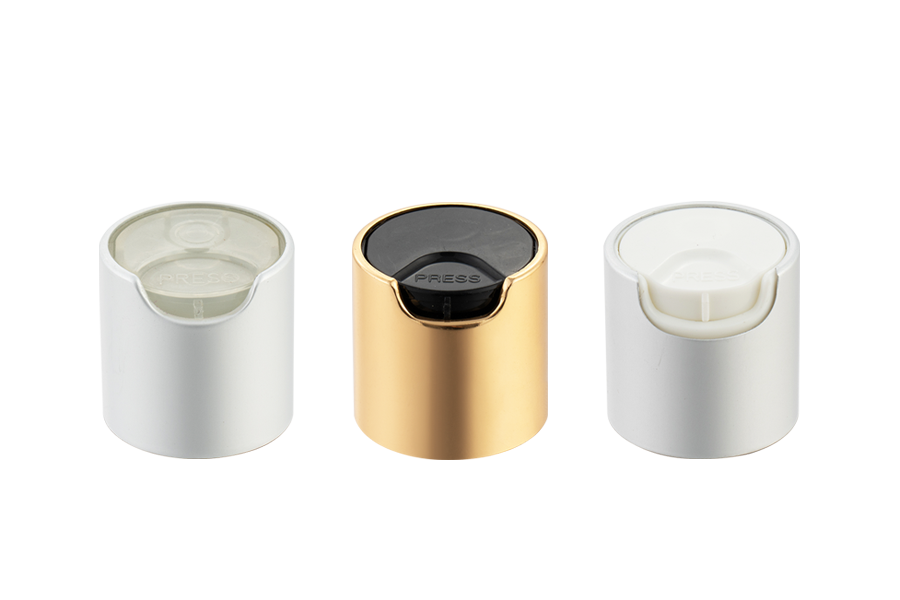

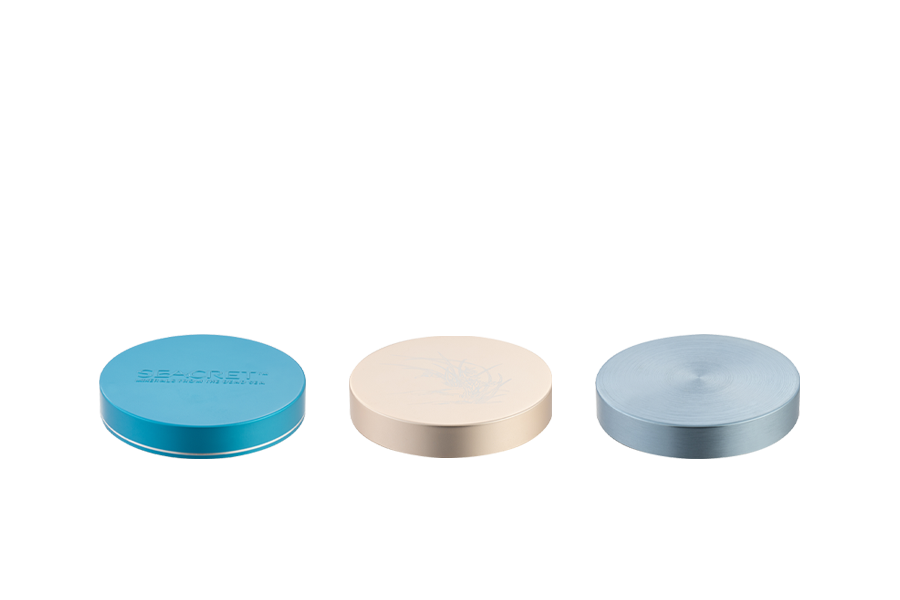

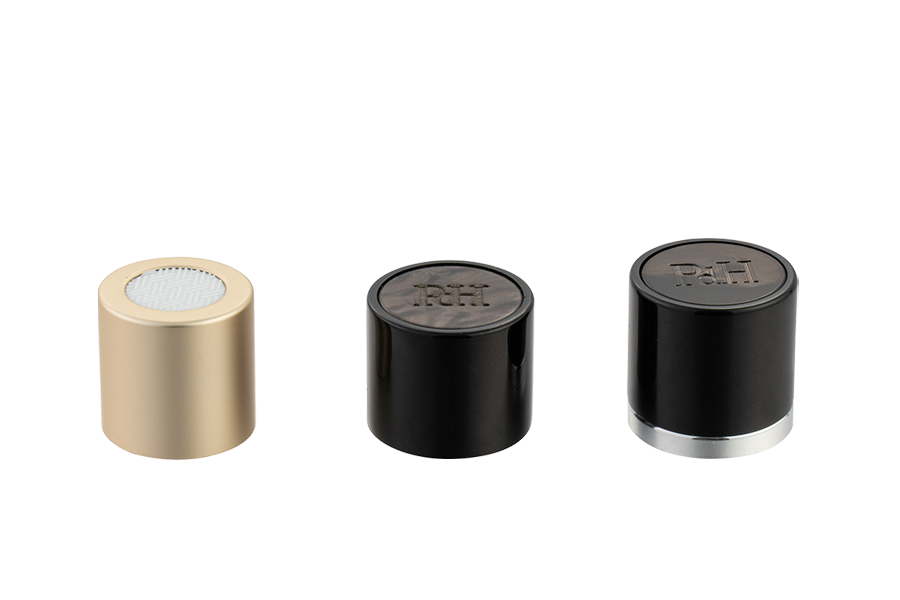

2. Plastic Top Cap (Plastic Components)

Located above the aluminum cap, this is the part the user directly contacts. It is typically made of PP (Polypropylene) material.

- Design: Can be designed as a "fully tear-off" or "partially tear-off" (flip-open) type according to requirements.

- Colors and Logo: The plastic components come in a variety of colors and can be embossed or screen-printed with brand logos to enhance brand recognition.

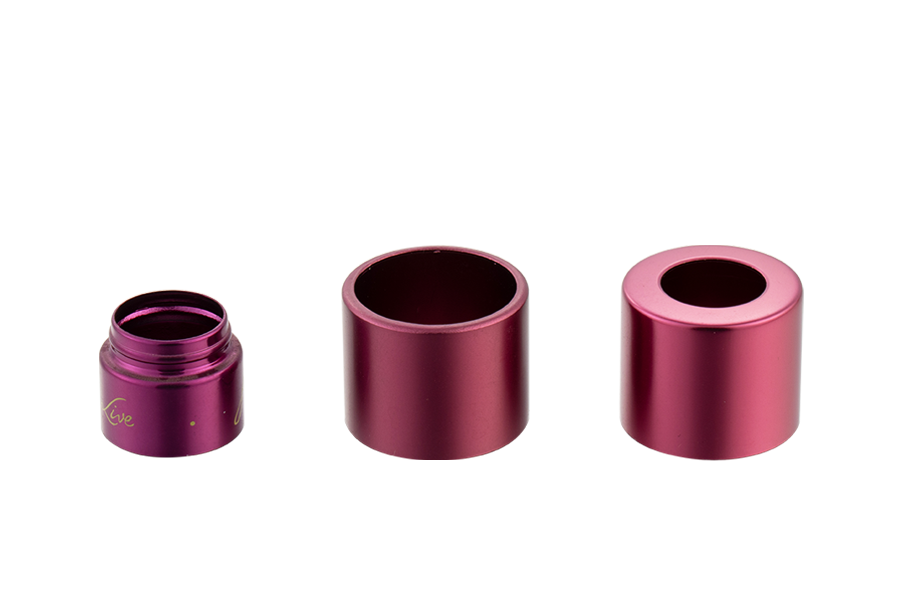

3. Riveting Point Structure (Connection Part)

This is a core indicator for evaluating the manufacturing process of aluminum-plastic caps. Manufacturers use professional riveting equipment to firmly bond the plastic top cap to the aluminum alloy body.

- Breakpoint Design: In high-quality aluminum-plastic caps, the riveting points should be evenly stressed when opened, ensuring a smooth and unbreakable tearing process.

III. Why Choose High-Quality Aluminum-Plastic Caps?

In practical applications, aluminum-plastic caps not only serve a decorative purpose but also work in conjunction with pharmaceutical glass bottles and butyl rubber stoppers to achieve a seal. If the structural design is unreasonable or the materials are substandard, it may lead to seal failure or metal burrs that could scratch operators.

As a professional aluminum-plastic cap manufacturer, we recommend focusing on the following when purchasing:

- Aluminum Thickness: Does it meet industry standards (e.g., 0.2mm)?

- Match Gap: Is the fit between the aluminum and plastic parts tight and free of looseness?

- Cleanliness: Is it produced in a standard cleanroom to ensure no aluminum shavings remain?

Understanding the structure and definition of aluminum-plastic caps helps companies choose more suitable packaging solutions. As a core keyword, the aluminum-plastic cap not only represents a component, but also serves as a crucial barrier to ensure product safety.

简体中文

简体中文 English

English