In the modern packaging industry, the quality of sealing technology directly affects the shelf life and safety of products. Especially in the pharmaceutical, biological product, and high-end cosmetic fields, the application of aluminum-plastic caps is becoming increasingly widespread.

Content

I. What is an Aluminum-Plastic Cap?

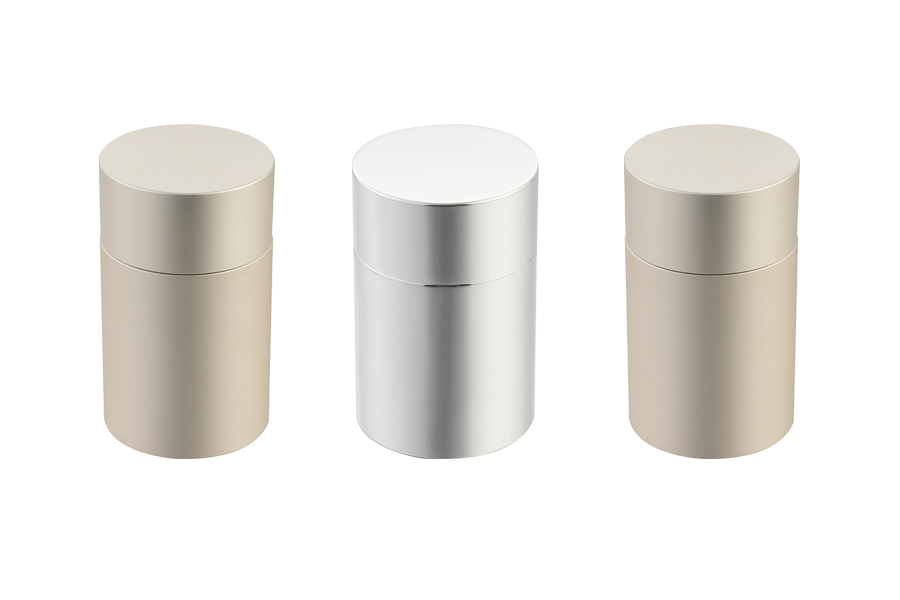

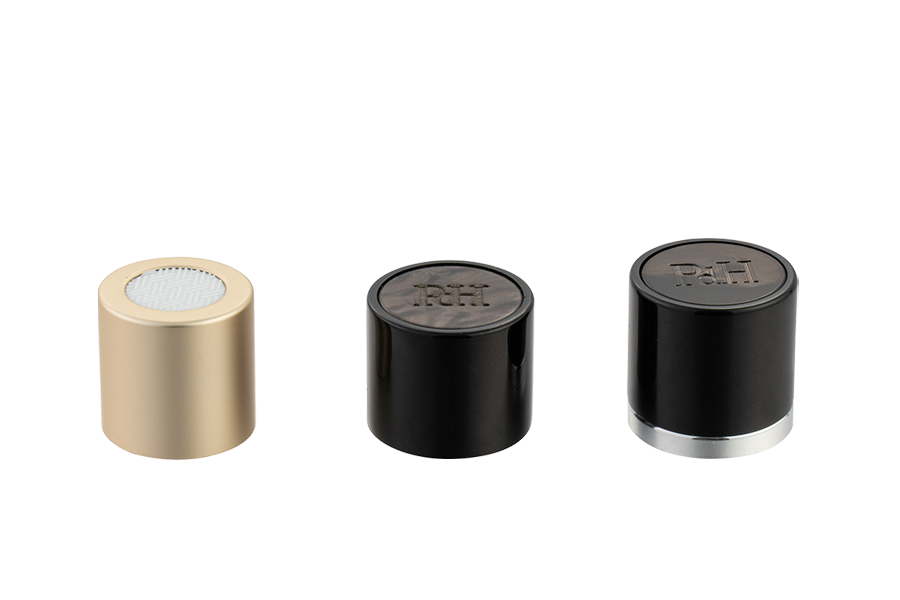

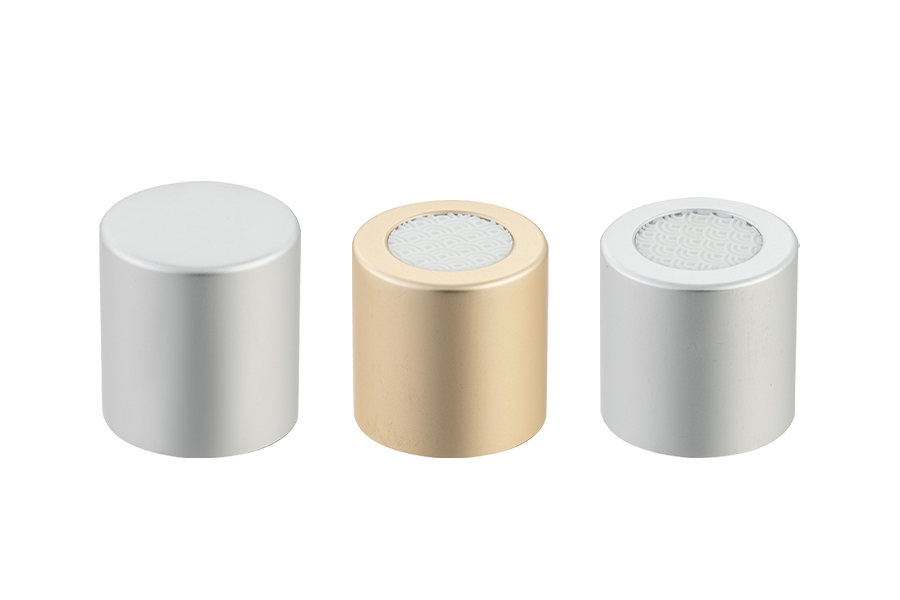

An aluminum-plastic cap is a composite sealing cap made by riveting an aluminum alloy cap and a plastic cap (usually made of PP). It combines the durability of metal materials with the versatility of plastic materials, making it the preferred packaging accessory for vials, oral liquid bottles, and injection vials.

As a high-performance packaging consumable, aluminum-plastic caps not only provide excellent sealing performance but also greatly improve the ease of opening through their unique "tear-off" or "peel-off" design.

II. Differences between Aluminum-Plastic Caps and Regular Aluminum Caps

Although both contain aluminum, in practical applications, aluminum-plastic caps are superior to regular aluminum caps in several dimensions.

1. Structural Upgrades

Standard Aluminum Caps: Simple structure, usually stamped from a single sheet of aluminum alloy.

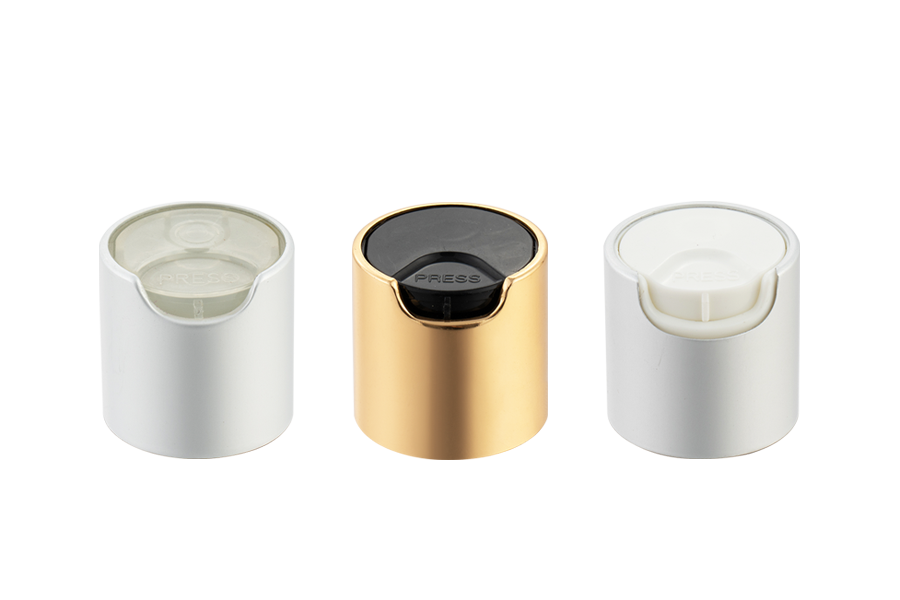

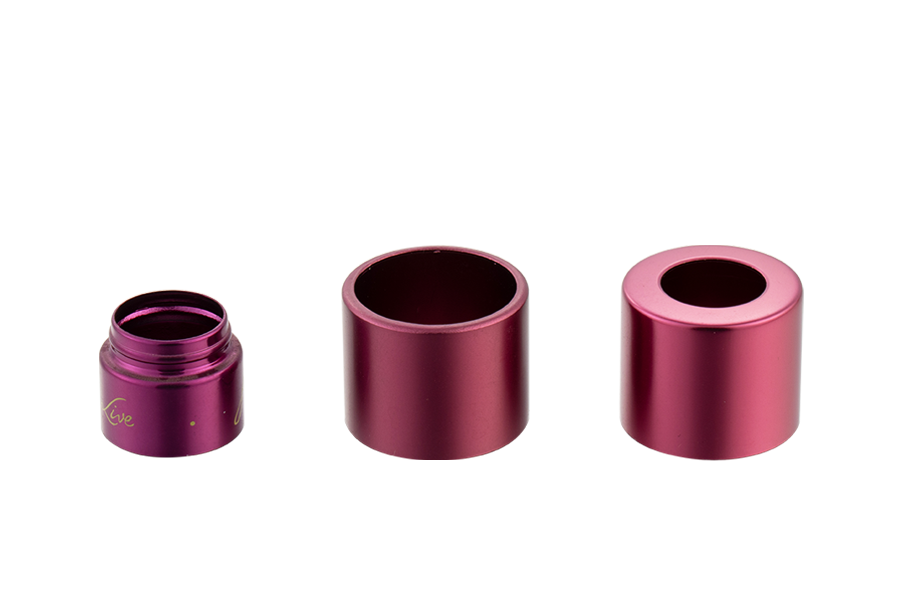

Aluminum-Plastic Caps: Composite structure. The upper layer is a colored plastic cap, and the lower layer is an aluminum ring. This design allows for puncture and dispensing of medication simply by removing the plastic top cap without disrupting the seal, greatly protecting the cleanliness of the container opening.

2. Safety and Anti-counterfeiting Performance

Standard Aluminum Caps: Easily leave sharp metal burrs after opening, posing a risk of scratches, and anti-counterfeiting measures are relatively simple.

Aluminum-Plastic Caps: The plastic cap can be customized in color or laser-printed, providing strong anti-counterfeiting features. Once the plastic cap is opened, irreversible opening marks are left, effectively preventing refilling and tampering.

3. Opening Experience and Convenience

Standard Aluminum Caps: Often require a cap opener or other tools, and improper operation can easily produce metal shavings.

Aluminum-Plastic Caps: More user-friendly design. Whether fully tear-off or partially tear-off, users can easily open the bottle with a simple pry, providing a better user experience and preventing metal shavings from falling into the bottle and contaminating the liquid.

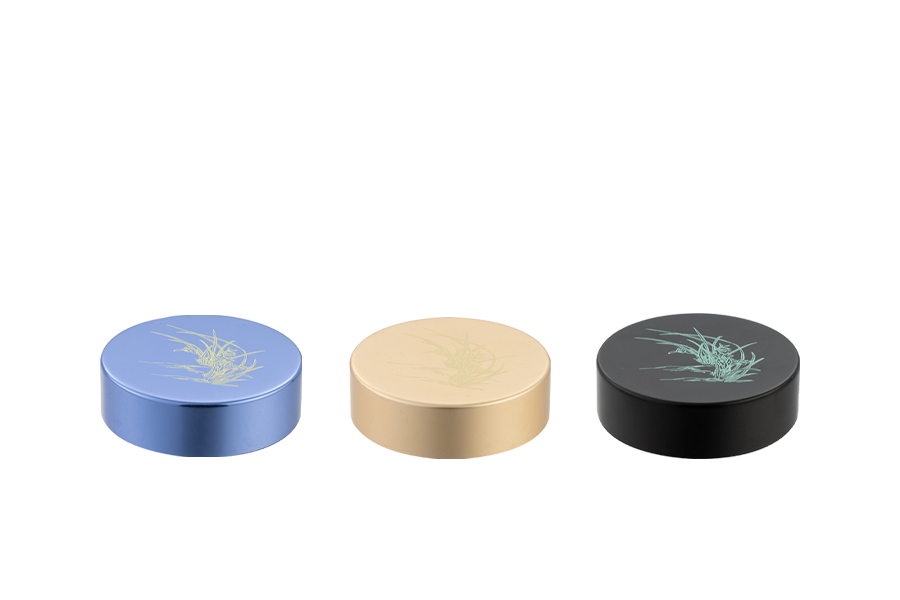

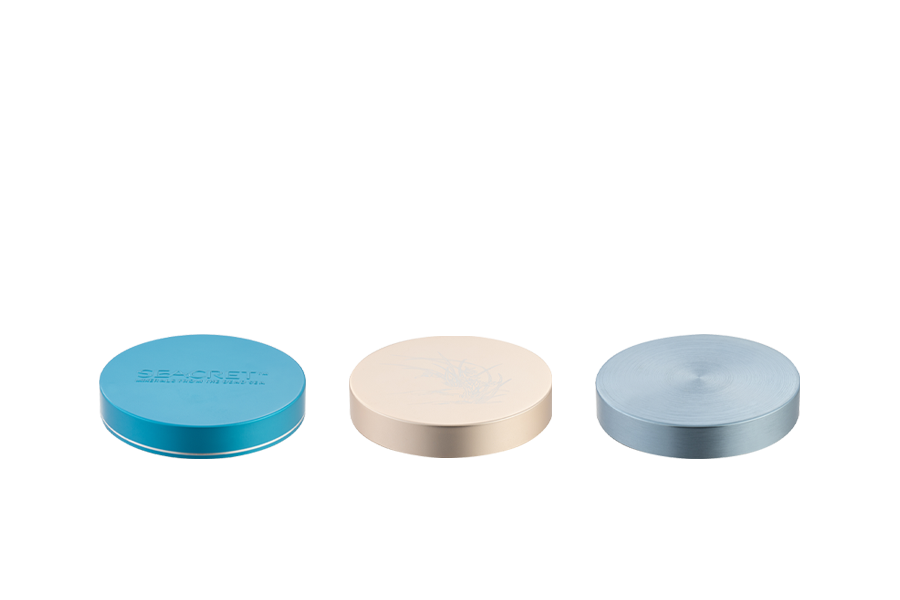

4. Aesthetics and Brand Display

The plastic portion of the aluminum-plastic cap can be customized in various vibrant colors (such as sky blue, grass green, burgundy, etc.) according to customer needs, and can even have a brand logo molded on. This not only enhances the product's grade but also strengthens brand recognition, something that ordinary aluminum caps of a single color cannot match.

III. Why do manufacturers prefer aluminum-plastic caps?

- Excellent physical properties: Resistant to high-temperature and high-pressure sterilization (e.g., no fading or deformation at 121°C/30 minutes).

- Extremely high adaptability: Precisely matches various sizes of vials and rubber stoppers, ensuring airtightness.

- Compliant with GMP standards: High cleanliness during the production process, low heavy metal residue, meeting medical-grade hygiene requirements.

Aluminum-plastic compression caps are not just an upgraded version of ordinary aluminum caps; they are a product that combines functionality and aesthetics. If you are looking for enhanced packaging security, stronger brand expression, and a superior user experience, aluminum-plastic compression caps are your best choice.

简体中文

简体中文 English

English