Against the backdrop of global efforts to ban plastics and achieve carbon neutrality, aluminum cans, as an "environmentally friendly star" in beverage packaging, are gaining increasing favor from brands and consumers.

Content

Aluminum Cans: The Packaging Container with the Highest Recycling Rate Globally

According to authoritative industry data, aluminum cans are among the packaging containers with the highest recycling rates in the world. In some developed countries and regions, the recycling rate of aluminum cans even exceeds 90%. In China, thanks to a mature waste metal recycling system, the overall recycling rate of aluminum cans (beverage cans) has consistently ranked among the top.

In contrast, the recycling process for plastic bottles (PET) is complex and prone to degradation, while aluminum cans demonstrate extremely high commercial value and environmental friendliness.

Why are aluminum cans called "infinitely recyclable" packaging?

"Infinite recycling" is not a marketing slogan, but rather based on the unique physical properties of aluminum cans.

- Performance Never Declines: Unlike paper or plastic, which shortens fibers or breaks molecular chains after multiple recycling processes, aluminum, as a metallic element, retains its atomic structure during the smelting and recycling process. This means an old aluminum can can be remelted, rolled into aluminum foil or aluminum stock, and made into brand new aluminum cans with the same quality as virgin aluminum.

- Fast Closed-Loop Recycling: In an ideal recycling system, a discarded aluminum can can be collected, sorted, smelted, rolled, and returned to the shelf in as little as 60 days. This highly efficient "can-to-can" closed-loop cycle is unmatched by other packaging materials.

- Significant Energy Saving and Emission Reduction: The energy consumption for producing recycled aluminum is only about 5% of that for producing virgin aluminum (electrolytic aluminum). The electricity saved from recycling one aluminum can is enough to power a television set for 3 hours. For companies pursuing ESG (Environmental, Social, and Governance) goals, using aluminum can packaging is a crucial step in reducing the carbon footprint of their products and achieving a green supply chain.

Manufacturer's Perspective: Future Trends in Aluminum Can Packaging

As a professional aluminum can manufacturer, we have observed significant changes in the market:

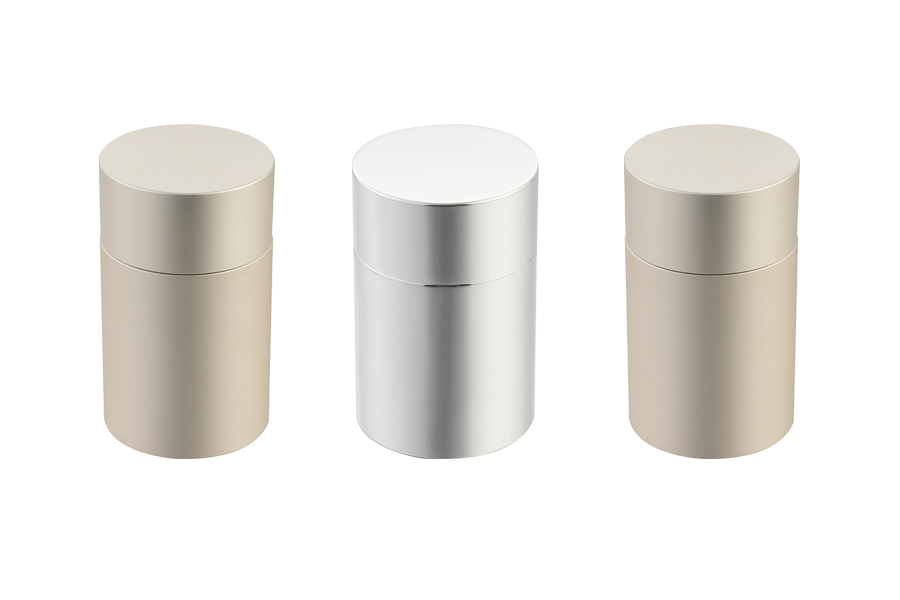

- Category Expansion: Beyond traditional carbonated beverages and beer, sparkling water, mineral water, and even spirits are now adopting aluminum can packaging to take advantage of its excellent light-blocking and airtight properties.

- Low-Carbon Aluminum Applications: More and more buyers are demanding cans made from "green aluminum" to meet increasingly stringent environmental export standards.

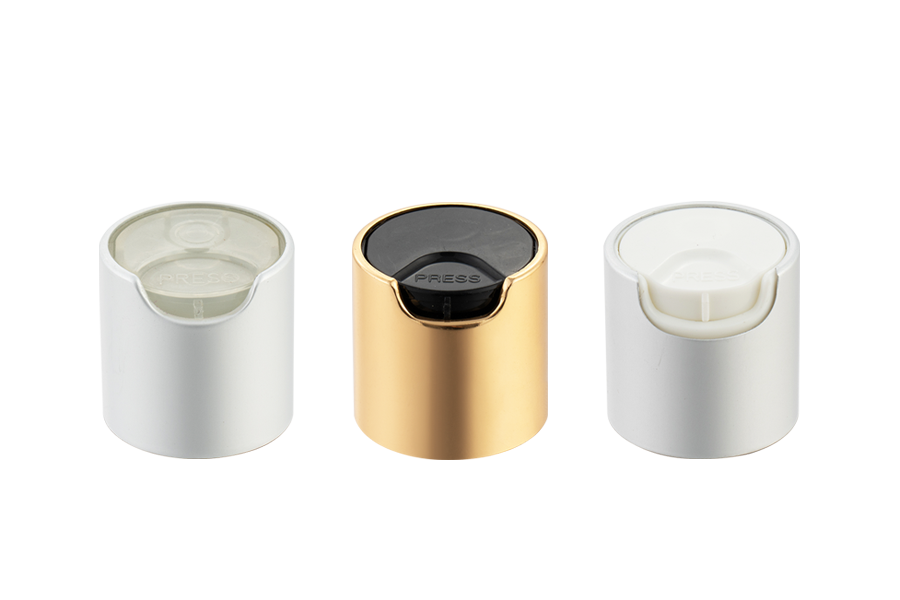

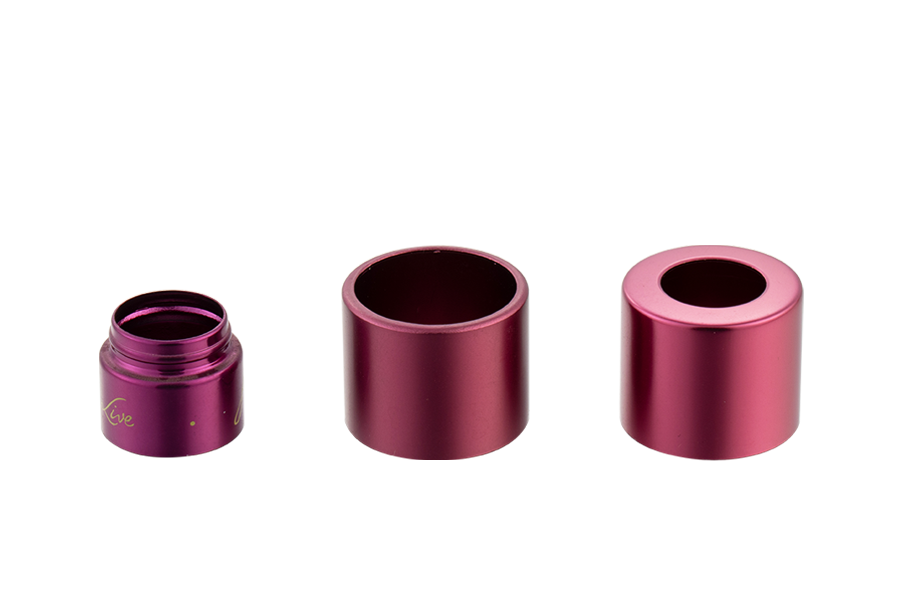

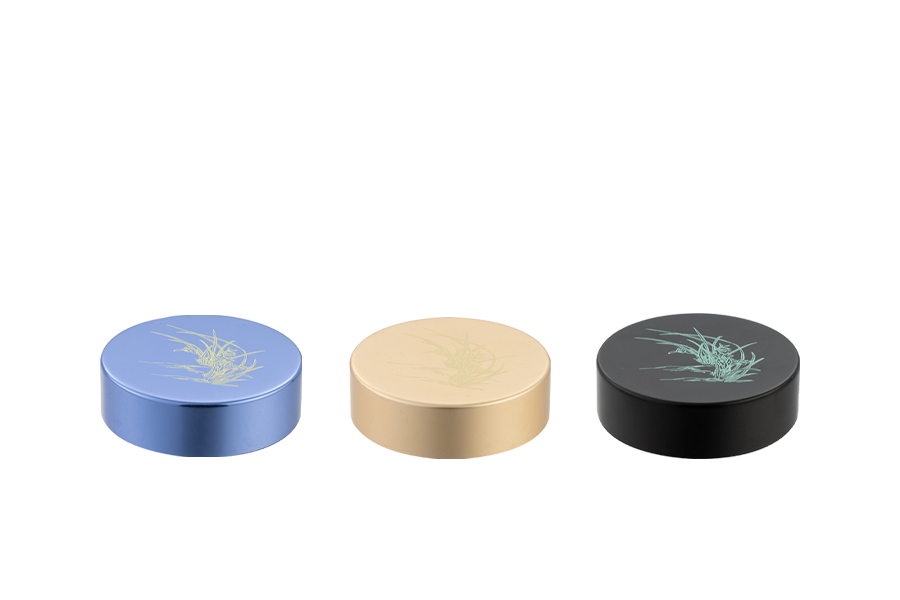

- Personalized Customization: Advanced printing processes allow for exquisitely detailed visual effects on aluminum can surfaces, enhancing brand premium.

Aluminum cans are not only containers for protecting liquids but also models of resource recycling. Choosing aluminum cans means choosing a sustainable future. As a leading aluminum can manufacturer, we are committed to providing high-quality, high-recyclability packaging solutions to our global customers.

简体中文

简体中文 English

English