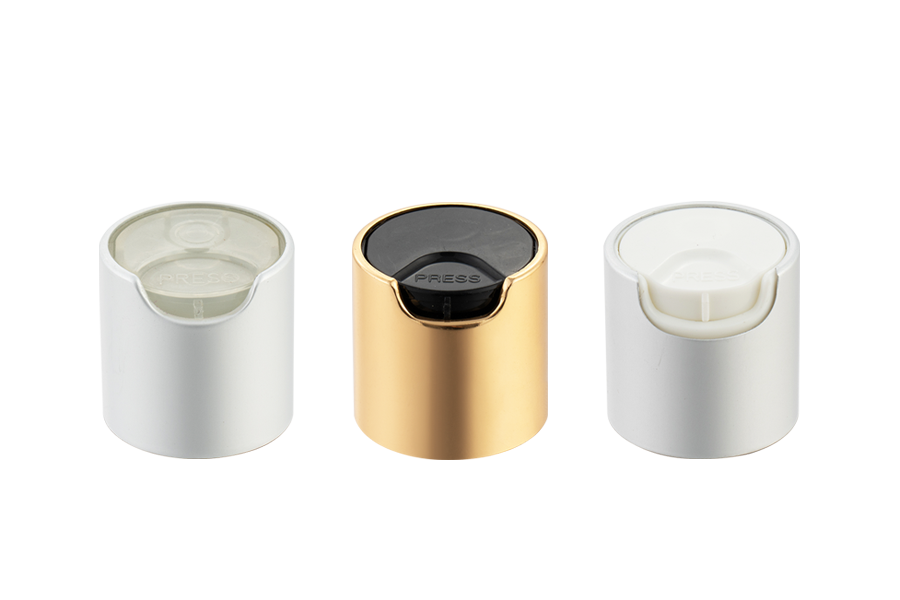

Press top caps are widely used in cosmetics packaging, personal care products, household cleaning products, and food condiments, primarily serving the functions of convenient opening and closing, precise dispensing, and leak prevention. This type of cap can be opened and closed with a gentle press of the fingertip on the edge, allowing for one-handed operation and greatly enhancing the user experience. Whether it's a shampoo bottle used in the shower or dish soap packaging in the kitchen, the press top cap is a core component that improves product usability.

Content

Application Scenarios of press top Caps

With consumer upgrading, the interactive experience of packaging materials is becoming increasingly important. Thanks to their structural advantages, press top caps have gained significant importance in the following industries:

1. Beauty and Personal Care

In products such as shampoos, conditioners, shower gels, and body lotions, press top caps are the absolute mainstream. Users often only have one hand available during showering, and this "press-to-open" design avoids the embarrassment of dropping or losing screw-on caps. At the same time, the compact internal structure effectively prevents water from entering the bottle.

2. Household Cleaning and Care

For dish soap, leather care liquids, or floor cleaners, press top caps provide better flow control. The small opening created by pressing allows users to precisely control the amount of liquid dispensed, avoiding waste and maintaining cleanliness around the bottle opening.

3. Industrial and Laboratory Lubrication

In some industrial settings that require frequent application of lubricating oil or precision cleaning agents, press top caps, combined with specially designed bottles, enable quick replenishment and improve work efficiency.

Why do brands prefer press top caps?

For manufacturers, choosing press top caps is not only about functionality but also about product positioning and cost-effectiveness:

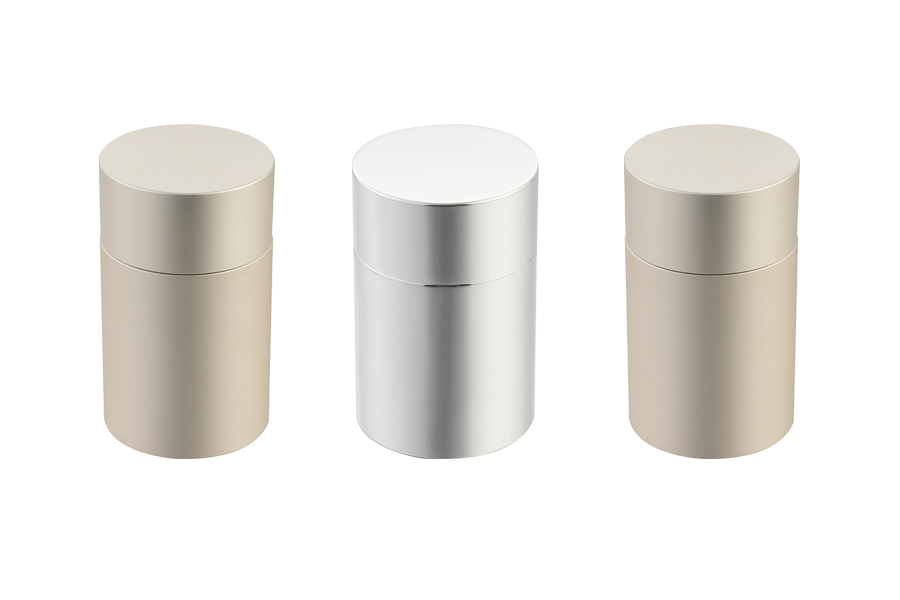

Excellent Sealing Performance: High-quality press top caps have built-in sealing rings or precisely fitted stoppers, providing excellent leak-proof performance when closed, ensuring that liquids do not leak even during long-distance transportation and courier delivery.

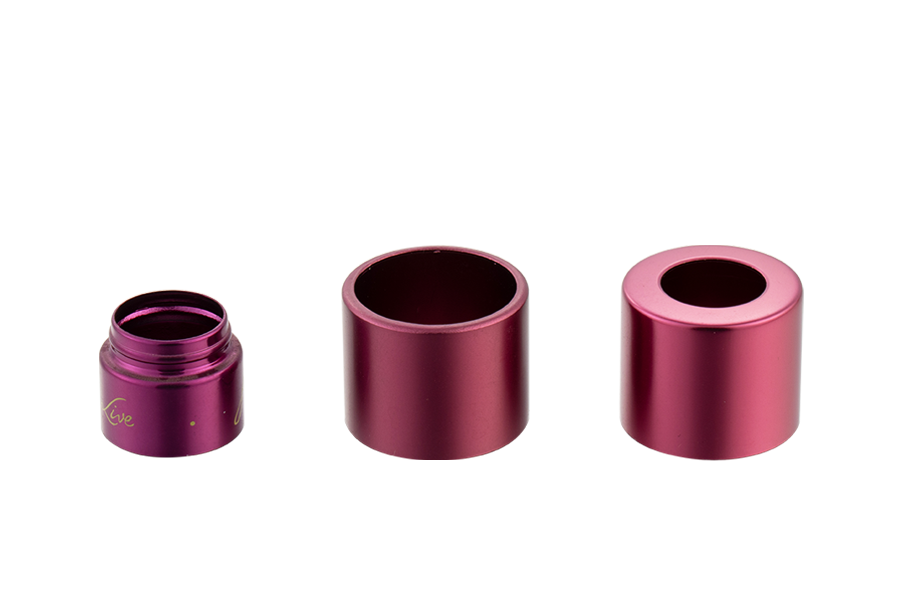

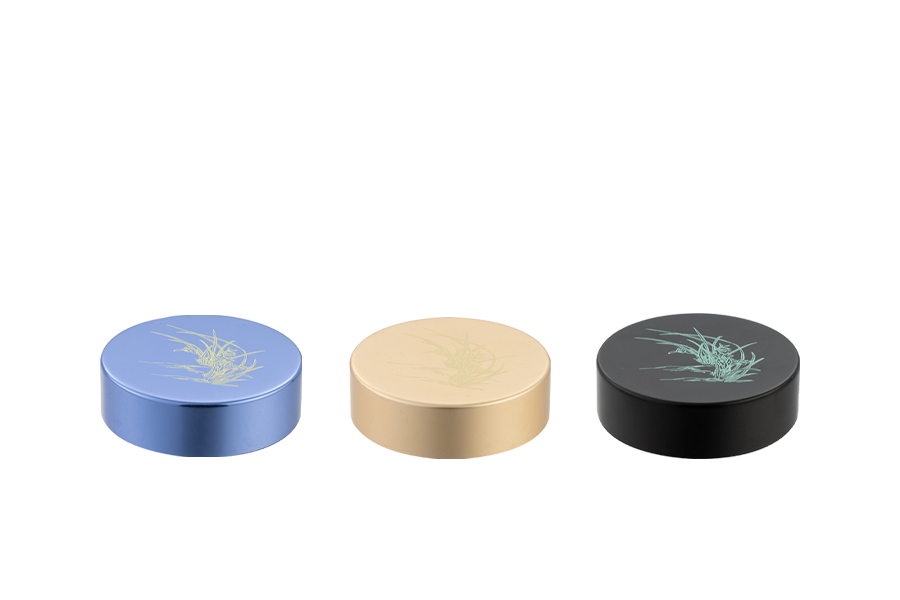

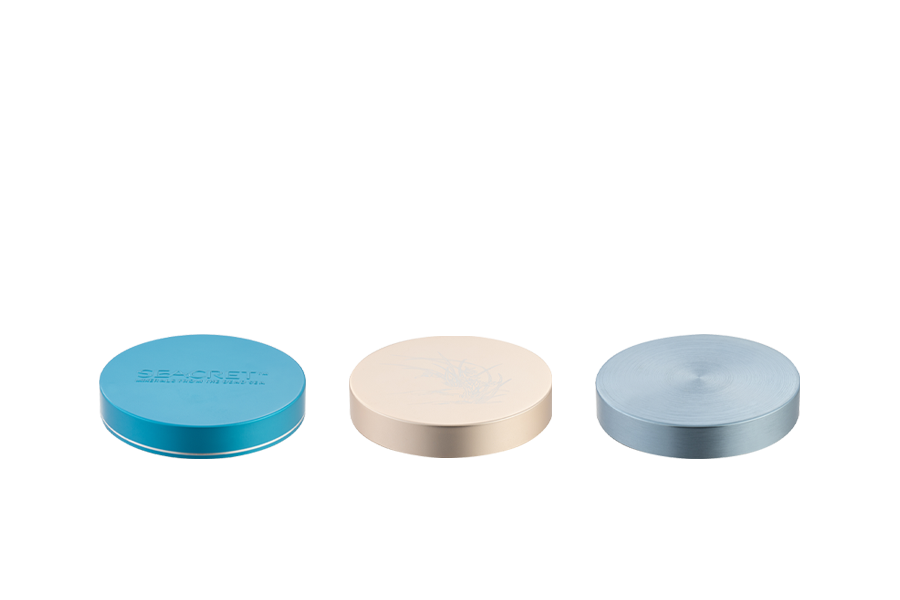

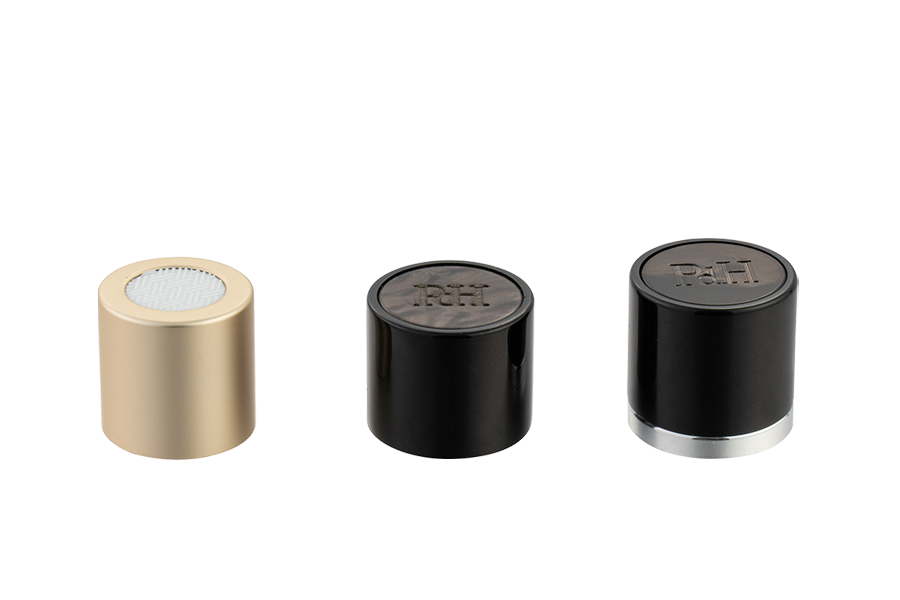

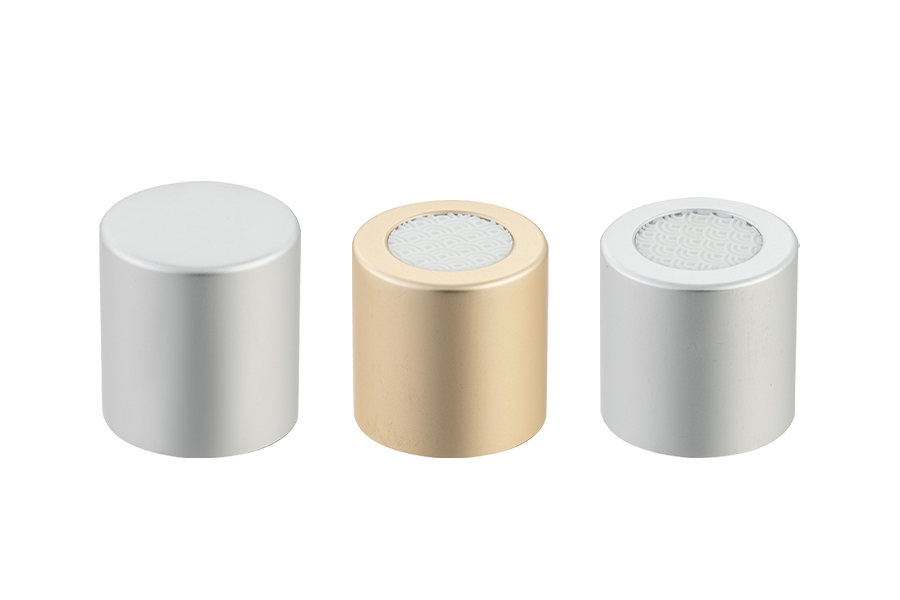

Diverse and Customizable Appearance: These caps can be made using two-color injection molding processes and can even be electroplated with gold or silver finishes, greatly enhancing the visual appeal of the product packaging.

Environmentally Friendly and Recyclable Materials: Modern, efficient plastic cap manufacturers often use polypropylene (PP) material for production. This material has strong chemical resistance and is recyclable, aligning with the trend of green packaging.

How to Choose High-Quality Press-Type Caps?

When purchasing or designing products, the quality of press-type caps can be evaluated from the following professional dimensions:

Pressing Feel: An excellent spring mechanism should have moderate damping, a crisp sound, and remain functional after repeated pressing.

Compatibility: The cap's threads (such as 24/410, 28/410 specifications) must fit perfectly with the plastic bottle opening to prevent leakage.

Dispensing Port Design: Depending on the viscosity of the liquid (such as watery or creamy), a dispensing port with an appropriate diameter should be selected to ensure smooth and unobstructed dispensing.

As a container accessory that combines practical aesthetics and functionality, press-type caps have permeated every aspect of our lives. They not only simplify the user experience but also protect the active ingredients and safety of the product through their precise structure.

简体中文

简体中文 English

English