In the perfume, fine chemical, and pharmaceutical industries, product volatility remains a major challenge in packaging. Poor sealing can lead to the loss of active ingredients and potentially damage brand reputation.

Content

1. Selection and Application of High-Barrier Materials

The first line of defense in sealing comes from the material itself. For products containing alcohol, fragrances, or volatile solvents, conventional general-purpose plastics may swell or leak.

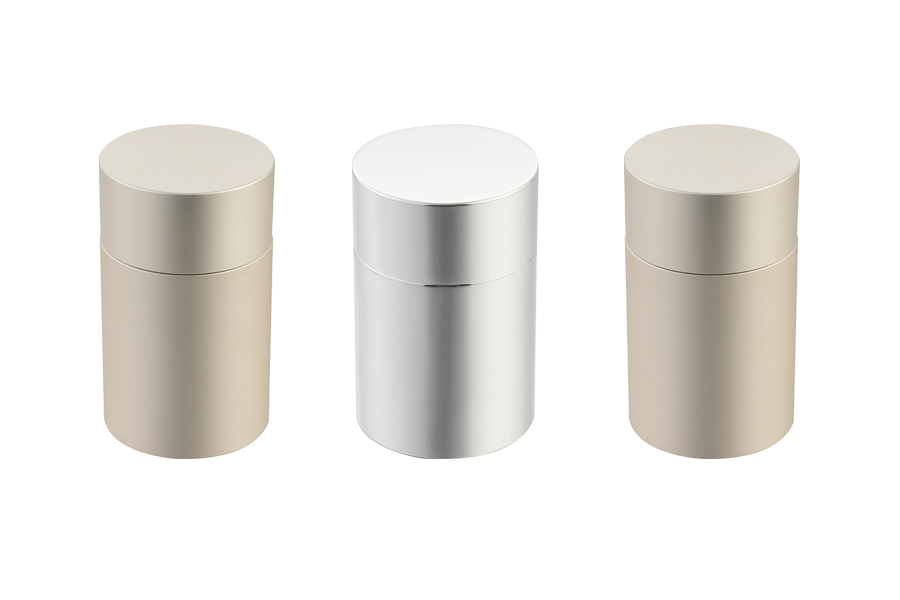

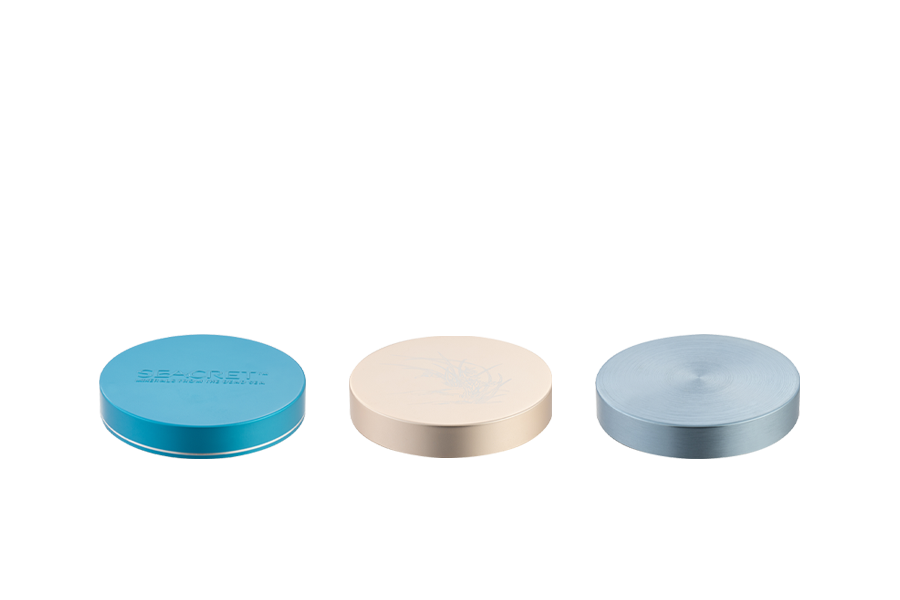

Material Optimization: We use high-density PP (polypropylene) or PETG as the base material for our Plastic Lid. These materials offer excellent chemical resistance and low permeability.

Modification Technology: By adding special barrier agents during the plastic cap manufacturing process, we can effectively seal the micropores between molecules, blocking the escape pathways of gas molecules.

2. Multi-layered Sealing System Design

Simply tightening the threads often fails to achieve a 100% seal; a deep structural design is key:

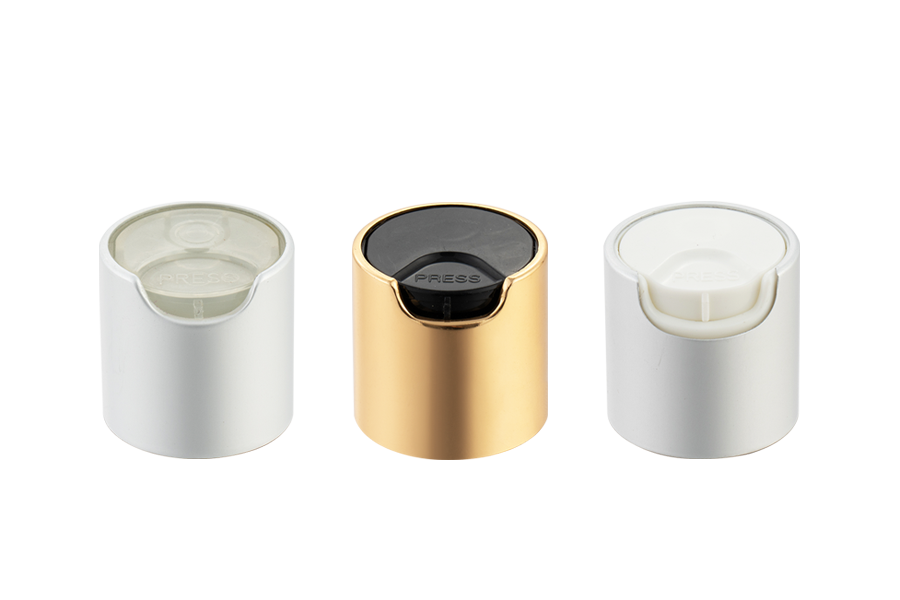

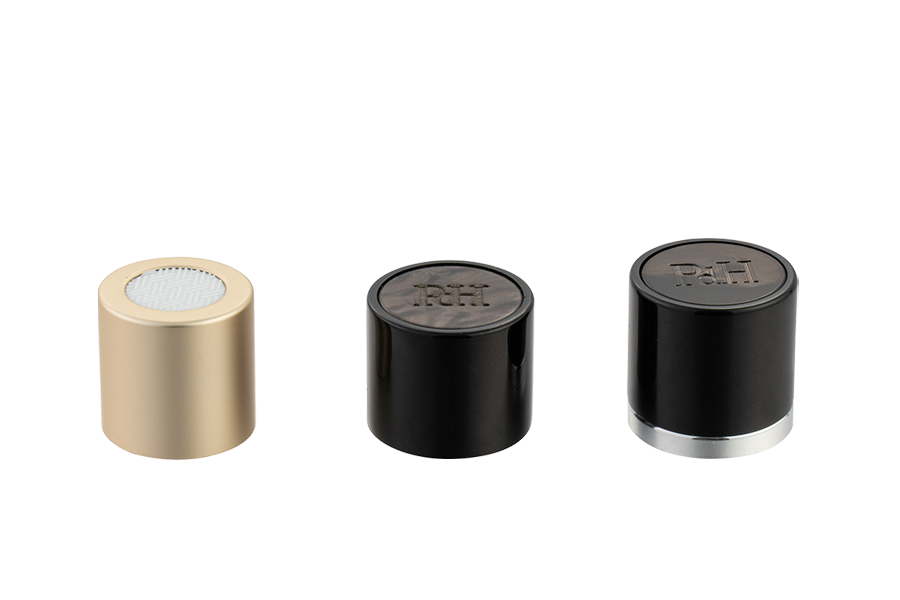

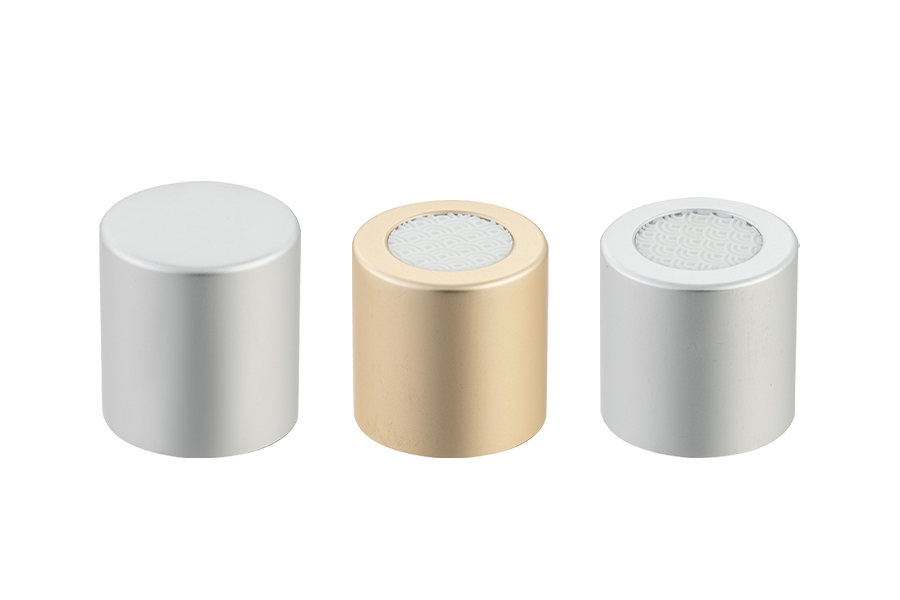

Inner Plug Structure: A precisely designed inverted conical inner plug seals the plastic cap. When the cap is rotated and pressed down, the inner plug tightly conforms to the inner wall of the bottle opening, forming a radial seal.

Double-layer Sealing Ring: For high-end perfume packaging, we design double sealing surfaces, combining the flatness of the bottle opening to achieve bidirectional sealing in both the longitudinal and lateral directions.

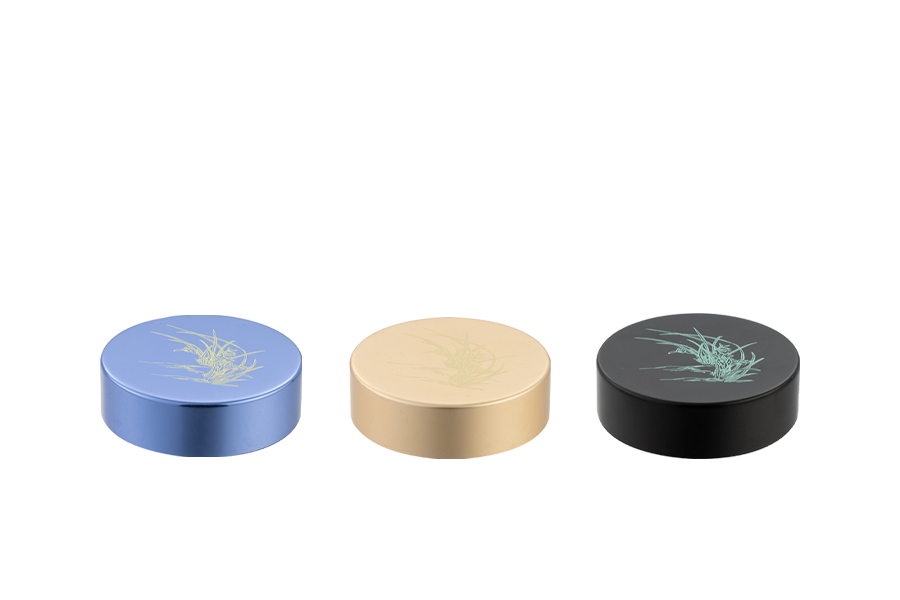

3. The "Catching Touch" of Functional Gaskets

Gaskets are the soul of enhancing the sealing performance of Plastic Lid. For volatile liquids, common solutions include:

Aluminum Foil Electromagnetic Induction Gaskets: Using induction heating, an aluminum foil layer is sealed to the bottle mouth, achieving complete physical isolation. This is currently the most robust method for preventing evaporation and leakage.

PTFE Coated Gaskets: Possessing extremely strong chemical inertness, these gaskets resist the corrosive effects of highly volatile chemicals, ensuring that the plastic cap does not deform or leak during long-term storage.

High-resilience PE foam pad: Utilizing the elasticity of the pad to compensate for minor unevenness at the bottle opening, ensuring a strong seal and preventing gas leakage.

4. Precision Torque Control and Anti-loosening Design

During transportation of volatile products, vibration can cause the plastic cap to loosen, instantly causing the seal to fail.

Anti-pull thread: Our Plastic Lid are designed with a scientifically calculated thread helix angle, providing greater frictional self-locking force.

Child lock (CRC) mechanism: This double-layer structure not only prevents children from accidentally opening the cap, but its downward-screwing mechanism also indirectly increases the pressure on the sealing surface, enhancing the overall safety of the packaging.

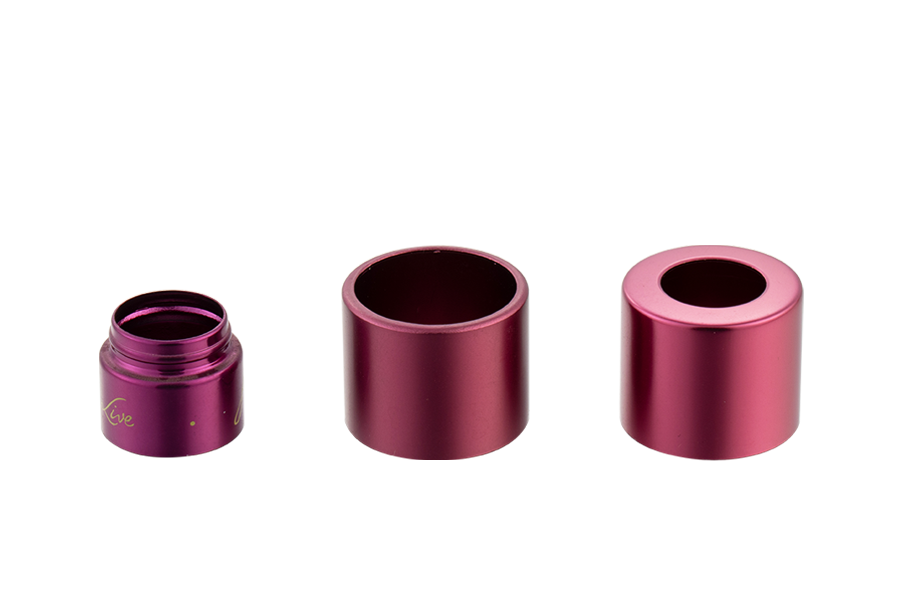

A high-quality plastic cap is not only the "outer garment" of the product, but also a "shield" protecting the core formula. Through a combination of personalized design and customized materials, we are committed to providing global customers with safer, more environmentally friendly, and more efficient packaging solutions.

简体中文

简体中文 English

English