In the perfume packaging industry, bottle caps are not only tools for sealing containers but also an extension of brand image. Currently, the mainstream choices on the market include all-plastic caps, pure aluminum caps, and Aluminum Plastic Fragrance Lid.

Content

1. Balance of Visual and Tactile Experience: High-End Metallic Texture

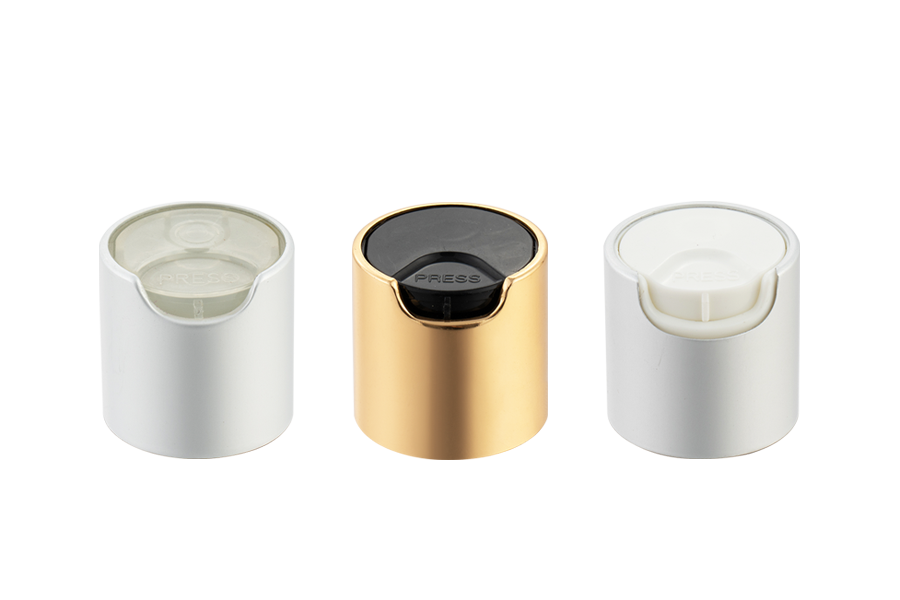

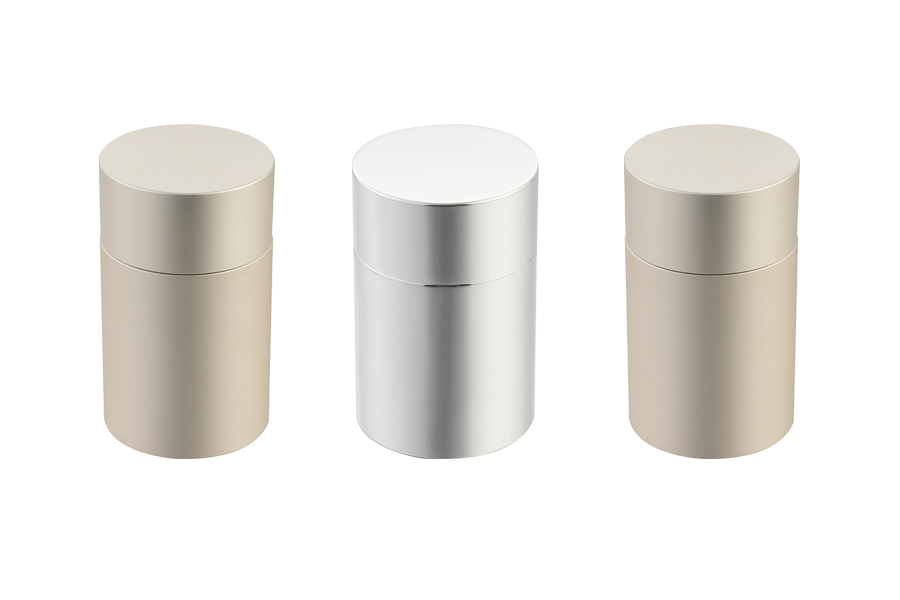

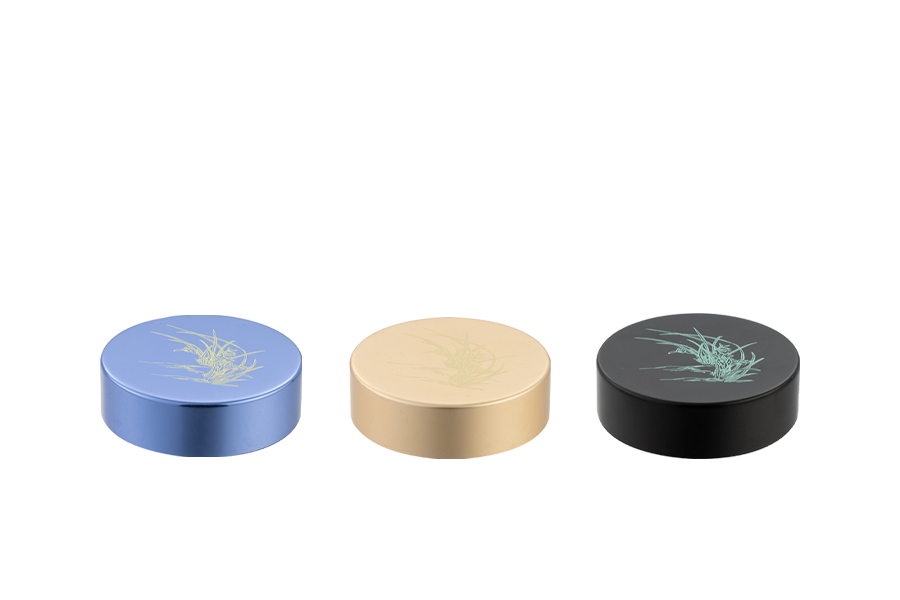

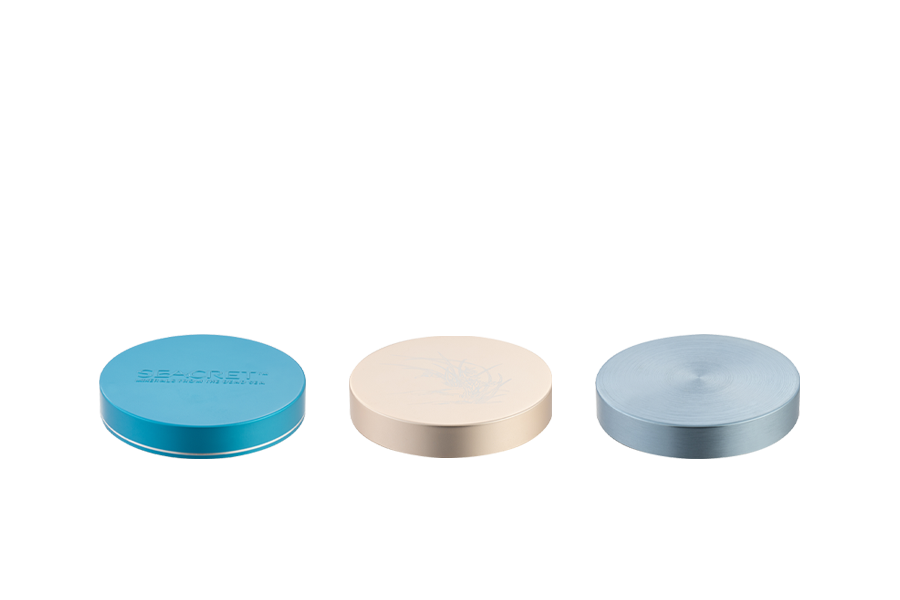

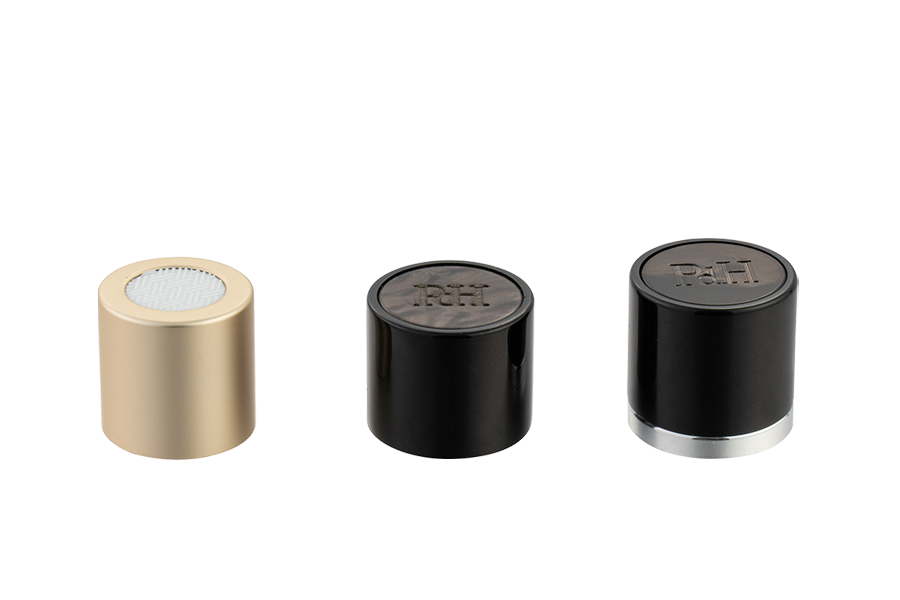

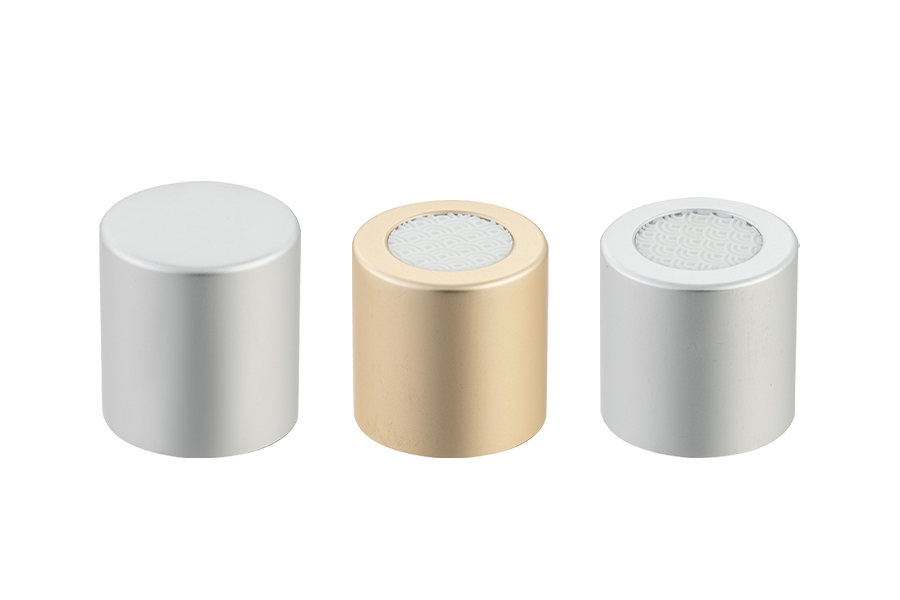

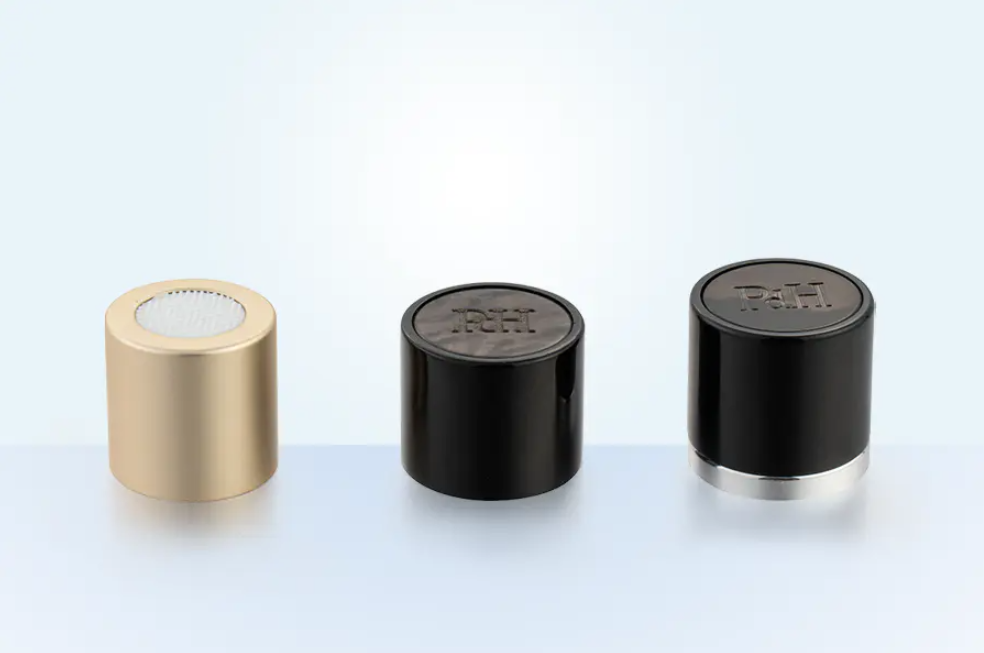

While all-plastic caps (such as PP or ABS) are low-cost, they often lack a sense of weight, making it difficult to support the premium pricing of high-end perfumes. Aluminum Plastic Fragrance Lid, on the other hand, use high-quality aluminum as the outer layer, and after anodizing, they can present rich metallic colors such as bright gold, matte silver, and gunmetal.

- Cool Metallic Feel: When consumers touch aluminum-plastic caps, they can feel the unique coolness and weight of metal.

- Versatile Processes: The aluminum shell surface can be customized with brushed, laser-engraved, or embossed logos, offering a visual refinement far exceeding that of plastic electroplating.

2. Structural Stability: Solving the Fragrance Corrosion Problem

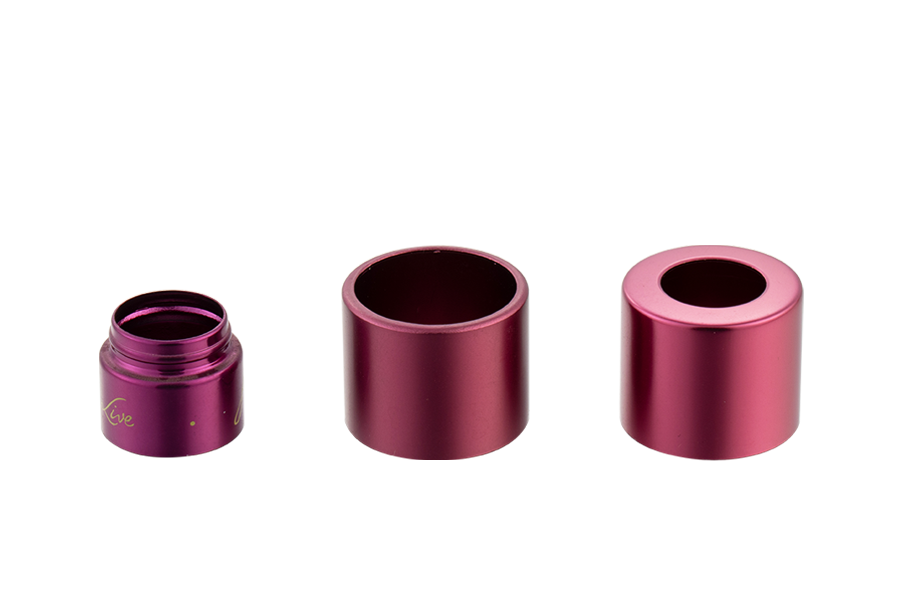

While all-aluminum caps are aesthetically pleasing, direct contact between aluminum and perfume can cause chemical reactions, leading to liquid deterioration or oxidation and corrosion on the inside of the cap. The aluminum-plastic perfume cap cleverly employs a double-layer structure of "outer aluminum, inner plastic":

- Inner Core Protection: The inner lining uses chemically stable materials (such as PP or Surlyn), effectively preventing fragrance solvents from corroding the metal outer shell.

- Sealing Performance: The plastic inner core possesses excellent toughness, allowing for a tighter fit with the pump head (FEA15/18, etc.), preventing perfume evaporation.

3. Optimization of Production Costs and Profit Margin

Compared to expensive zinc alloy caps or complex all-aluminum CNC machining, the aluminum-plastic perfume cap offers extremely high cost-effectiveness:

- Reduced Costs: The modular production of the internal structure reduces the overall aluminum consumption.

- Enhanced Prestige: It achieves a visual premium similar to metal caps with production efficiency approaching that of plastic caps, making it an ideal choice for affordable luxury perfume brands.

4. Physical Properties: Durable and Colorfast

The electroplating layer on the surface of all-plastic caps is prone to peeling and scratches after long-term use. In contrast, the anodized film on Aluminum Plastic Fragrance Lid has high hardness and excellent wear and scratch resistance. Even in humid environments or environments with large temperature fluctuations, it maintains its color and luster for a long time.

Aluminum Plastic Fragrance Lid, with their luxurious metallic appearance and inherent chemical stability, perfectly resolve the conflict between aesthetics and practicality. For perfume brands that pursue quality and are concerned about cost control, this is undoubtedly the most mature and reliable packaging solution currently available.

As a professional manufacturer of Aluminum Plastic Fragrance Lid, we provide a one-stop service from mold development and anodizing to assembly.

简体中文

简体中文 English

English