The core difference between aluminum-plastic perfume caps and all-plastic perfume caps lies in the combination of structural materials and overall performance: aluminum-plastic perfume caps adopt a composite design of “outer aluminum shell + inner plastic structure,” while all-plastic perfume caps use a pure plastic one-piece molded structure. In terms of appearance texture, durability, brand image, cost structure, and application scenarios, the two show obvious differences and are suitable for perfume packaging product lines with different positioning.

Content

- 1 Differences in structural material composition

- 2 Differences in appearance texture and brand image

- 3 Comparison of durability and structural stability

- 4 Differences in sealing performance and user experience

- 5 Differences in cost structure and market positioning

- 6 Comparison of environmental protection and sustainability

- 7 Application scenario adaptability analysis

- 8 Selection comparison summary table

Differences in structural material composition

Aluminum-plastic perfume cap:

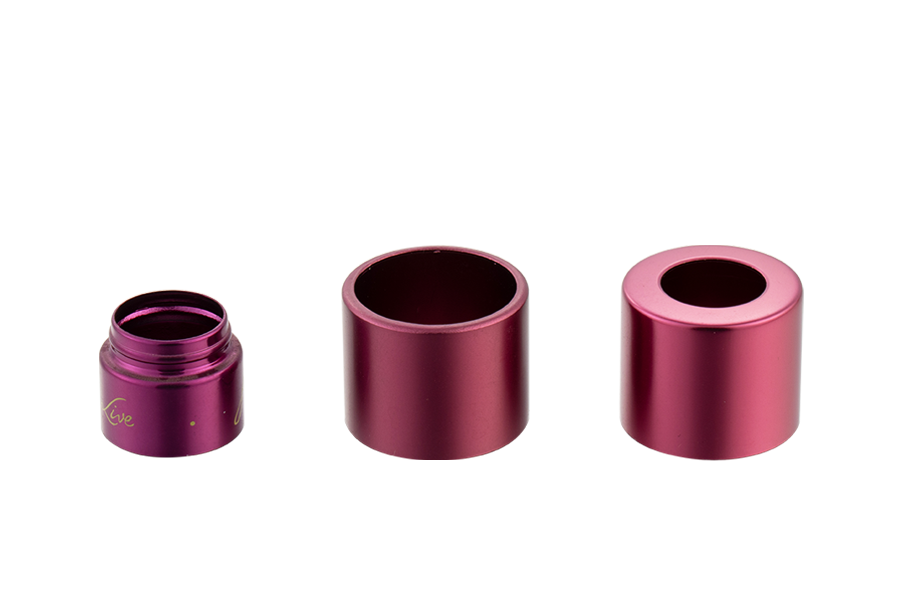

Outer layer: aluminum alloy shell

Inner layer: engineering plastic inner structure

Structure form: composite structure

Process: stamped aluminum shell + injection-molded inner liner + combined assembly

All-plastic perfume cap:

Material: plastics such as ABS / PP / PET

Structure form: one-piece molding

Process: injection molding

Aluminum-plastic perfume caps emphasize “metal texture + structural stability,” while all-plastic perfume caps emphasize “lightweight + cost control.”

Differences in appearance texture and brand image

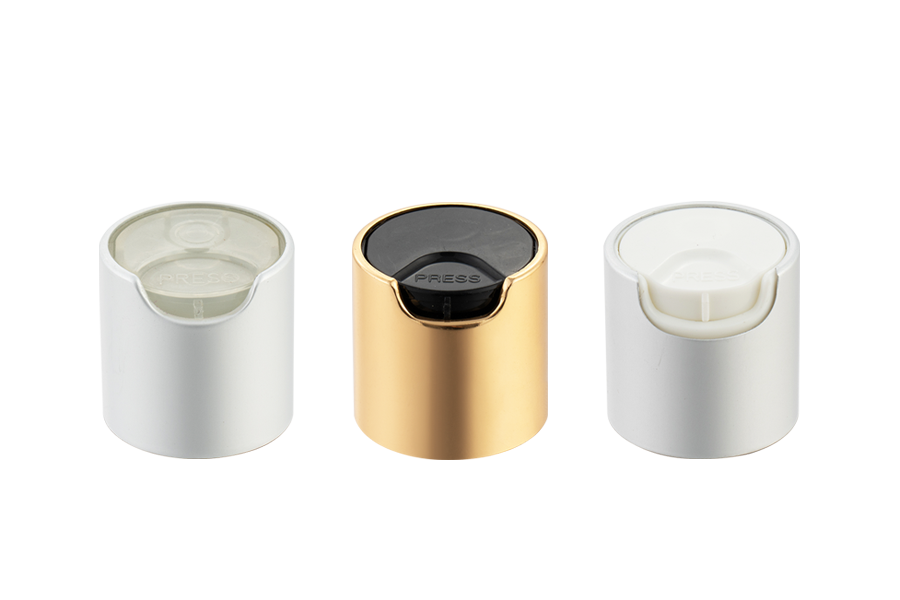

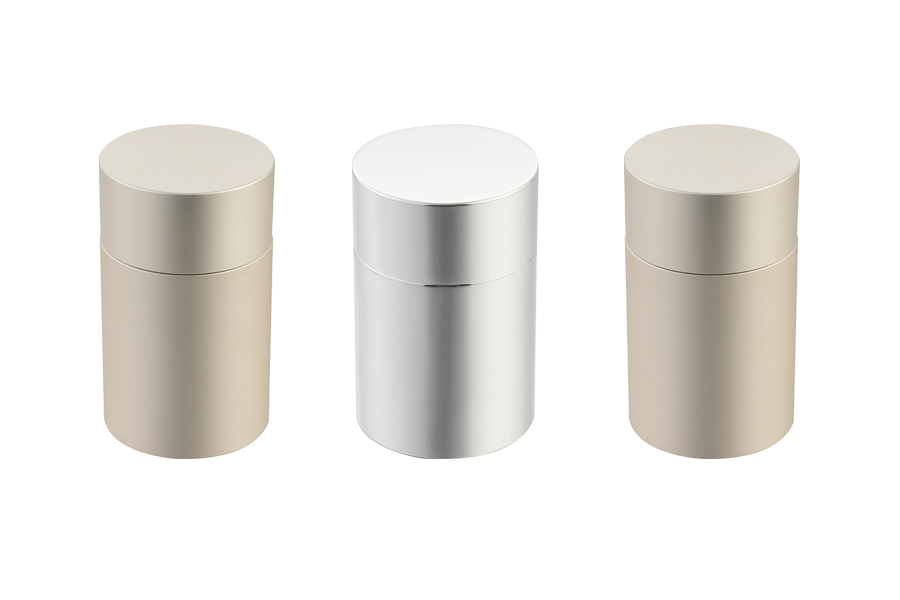

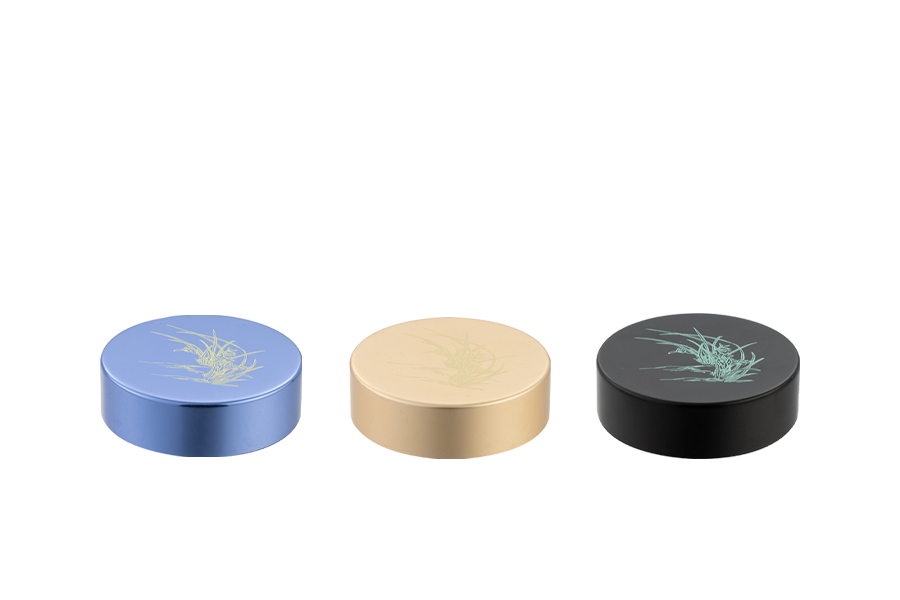

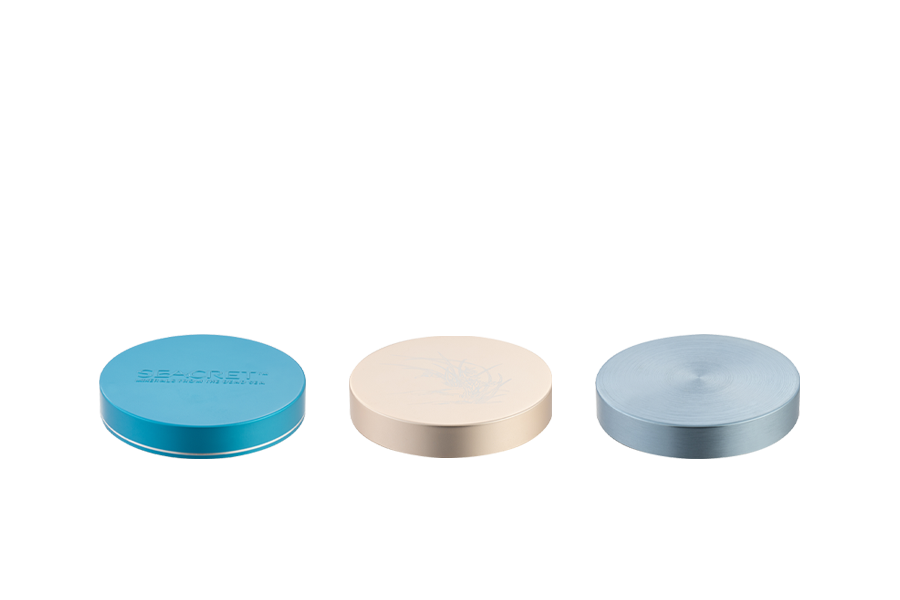

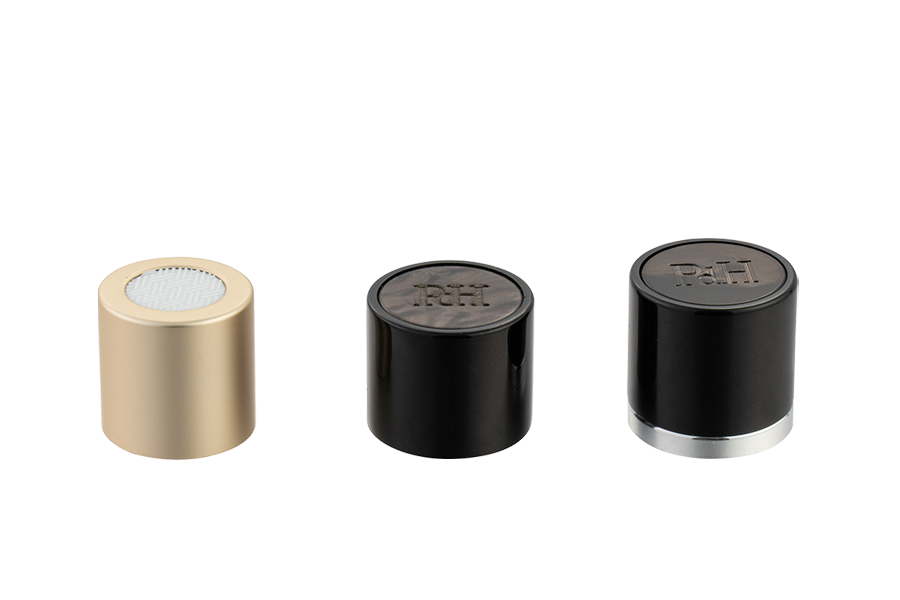

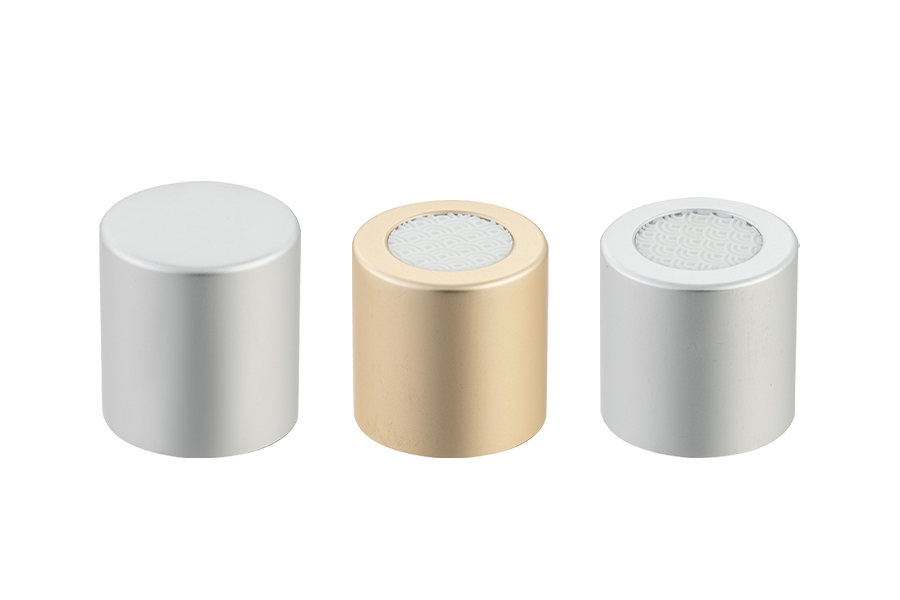

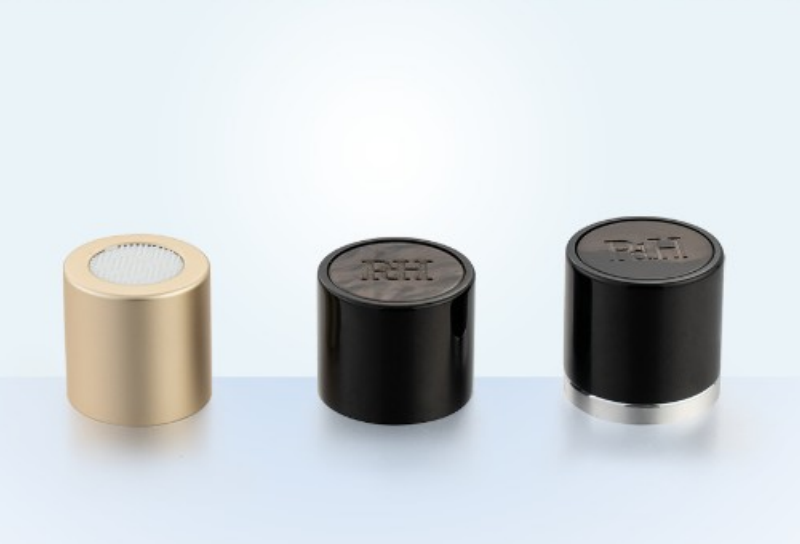

Advantages of aluminum-plastic perfume caps: strong metallic luster, obvious premium visual sense, diverse surface processes (anodizing, electroplating, brushing, sandblasting), more in line with high-end perfume packaging aesthetics.

Characteristics of all-plastic perfume caps: lightweight appearance, rich colors, high design freedom, texture tending toward a light industrial style.

In brand image shaping, aluminum-plastic perfume caps have stronger advantages in “high-end feeling” and “refined feeling.”

Comparison of durability and structural stability

| Comparison dimension | Aluminum-plastic perfume cap | All-plastic perfume cap |

| Deformation resistance | High | Medium |

| Aging resistance | High | Medium |

| Wear resistance | High | Medium |

| Structural stability | High | Medium |

| Service life | Long | Medium |

Aluminum-plastic perfume caps are more stable in long-term use and are not easy to age or deform.

Differences in sealing performance and user experience

Aluminum-plastic perfume cap: high structural fitting precision, inner plastic structure ensures sealing performance, stable screwing, solid hand feel

All-plastic perfume cap: sealing performance depends on mold precision, easily affected by temperature deformation, may loosen with long-term use

Aluminum-plastic perfume caps are more conducive to long-term sealing stability.

Differences in cost structure and market positioning

Aluminum-plastic perfume cap: higher material cost, complex process, long processing cycle, positioned for mid-to-high-end and high-end perfume brands

All-plastic perfume cap: low cost, high mass-production efficiency, suitable for large-scale production, positioned for the mass consumer market

Comparison of environmental protection and sustainability

Aluminum-plastic perfume cap: aluminum material is recyclable, detachable and recyclable structure, in line with green packaging trends

All-plastic perfume cap: plastic recycling is more difficult, environmental performance depends on material type

Under the trend of sustainable packaging, aluminum-plastic composite structures have greater environmental advantages.

Application scenario adaptability analysis

Applicable scenarios for aluminum-plastic perfume caps: high-end perfume brands, affordable luxury fragrance products, customized perfume packaging, gift-box perfumes, brand flagship series

Applicable scenarios for all-plastic perfume caps: mass-market perfume products, fast-moving consumer fragrance products, trial perfumes, e-commerce brand perfumes, large-batch production product lines

Selection comparison summary table

| Dimension | Aluminum-plastic perfume cap | All-plastic perfume cap |

| Material structure | Aluminum + plastic composite | Pure plastic |

| Appearance texture | High-end | Ordinary |

| Service life | Long | Medium |

| Cost | Medium–high | Low |

| Sealing stability | High | Medium |

| Brand adaptability | Mid-to-high-end | Mass-market |

| Environmental friendliness | High | Medium |

There is no “which is better” between aluminum-plastic perfume caps and all-plastic perfume caps, but rather “different positioning, different uses, and different scenarios.” Aluminum-plastic perfume caps are more suitable for mid-to-high-end perfume packaging that pursues brand texture, product grade, and long-term stability; all-plastic perfume caps are more suitable for product line layouts that emphasize cost control, rapid production, and mass market coverage.

简体中文

简体中文 English

English