This High Grade Sealed Vacuum Press Bottle Aluminum Lotion Bottle adopts a vacuum design. Its core advantage is that the product is pushed out of the bottle evenly through the air pressure difference, avoiding direct contact between the liquid in the bottle and the air throughout the process, thereby effectively isolating the invasion of oxygen, moisture and external pollutants. For skin care products containing easily oxidized active ingredients such as vitamin C, retinol, and plant essential oils, the vacuum environment can significantly delay the failure of the ingredients, maintain product stability, and extend the shelf life after opening.

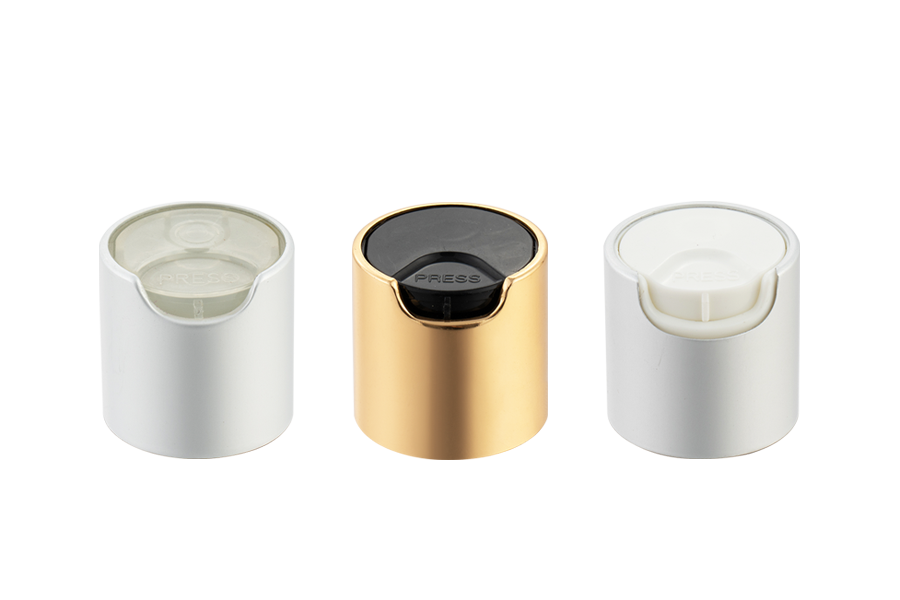

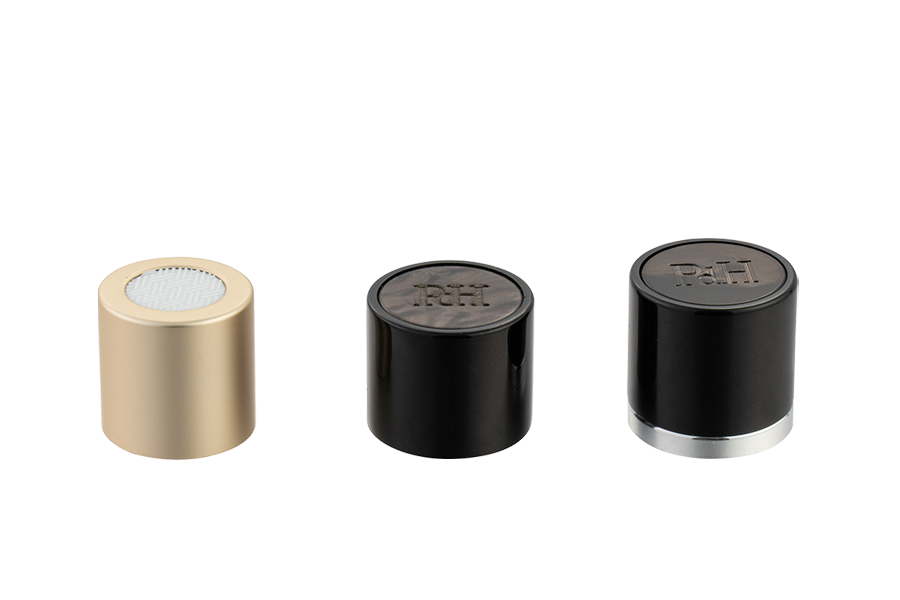

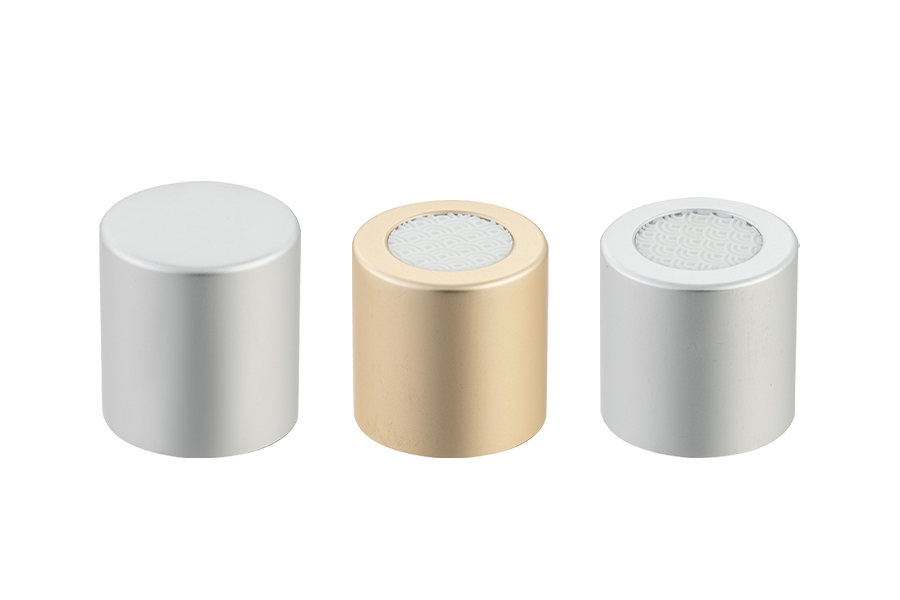

The pressing pump head equipped with this lotion bottle realizes quantitative liquid discharge through a precise mechanical structure. Users can obtain a stable and appropriate amount of product each time they press, avoiding uneven dosage or secondary contamination problems that may be caused by traditional open bottles or dropper designs. This feature is particularly suitable for high-concentration active ingredient products or medical-grade skin care products that require strict follow-up of dosage instructions. Quantitative use not only improves the convenience of use, but also helps users control skin care steps more scientifically to avoid skin burden or waste caused by excessive use.

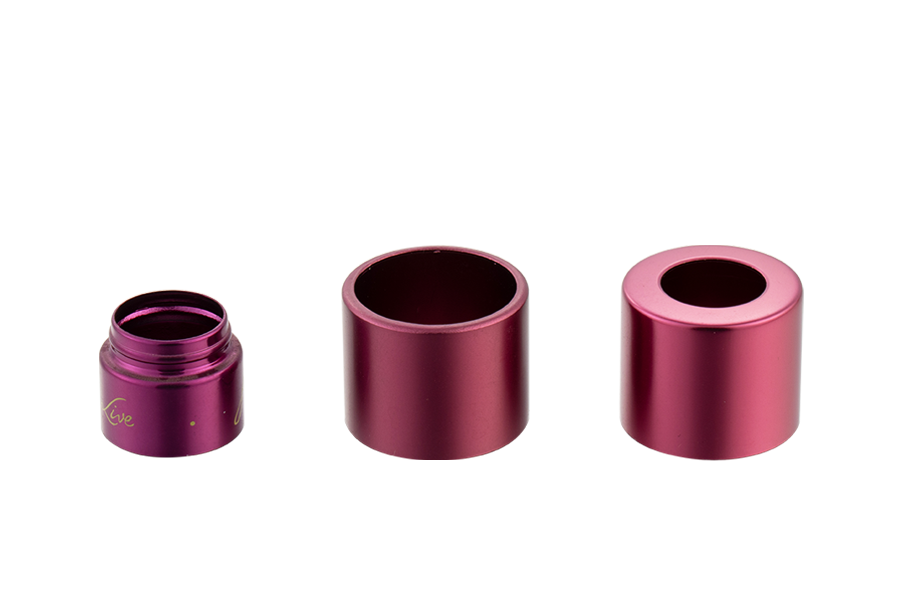

Its sealing design achieves a nearly fully enclosed storage environment through the dual protection of the screw cap and the vacuum pressing system. The screw cap adopts a high-precision thread structure to ensure that the bottle mouth and the bottle body fit tightly to prevent leakage during transportation or use; the vacuum pump head uses a one-way valve design to only allow the product to flow out in one direction to prevent external air or microorganisms from flowing back into the bottle. This feature makes it an ideal packaging choice for skin care products for sensitive skin, natural skin care products without preservatives, or children's skin care products, especially for products that need to remain sterile for a long time, such as medical dressings, postoperative repair lotions, etc.

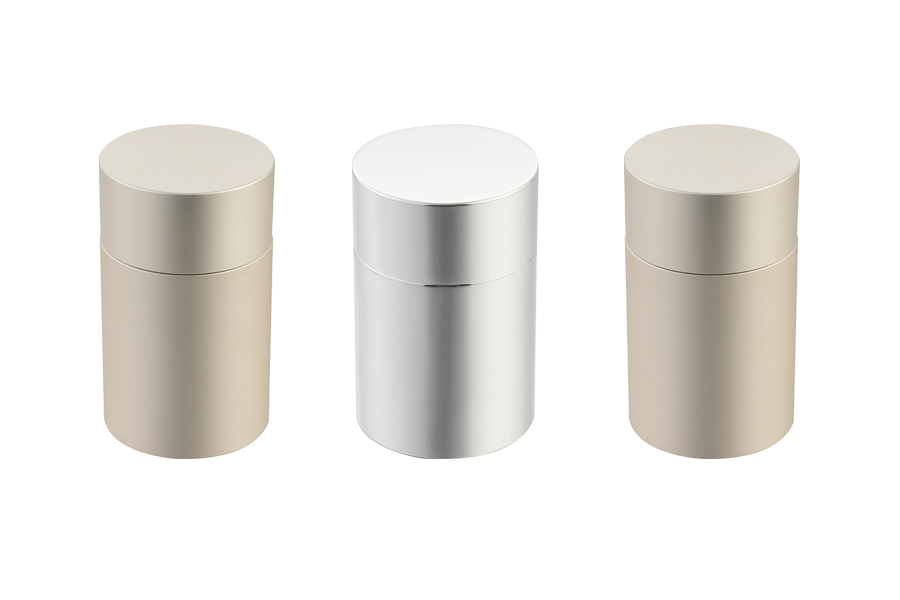

The aluminum bottle body is made of lightweight alloy material, which significantly reduces the overall weight while ensuring structural strength. Combined with the compact bottle body design, it can be easily put into a carry-on bag or suitcase to meet the skin care needs in travel scenarios. In addition, the aluminum surface is anti-scratch frosted, which not only improves the grip comfort, but also effectively resists collision and wear during transportation. For users who frequently go out or need to repack regular products, the portability and durability of this packaging can take into account both practicality and safety, such as portable sunscreen, emergency repair essence and other scenario-based products.

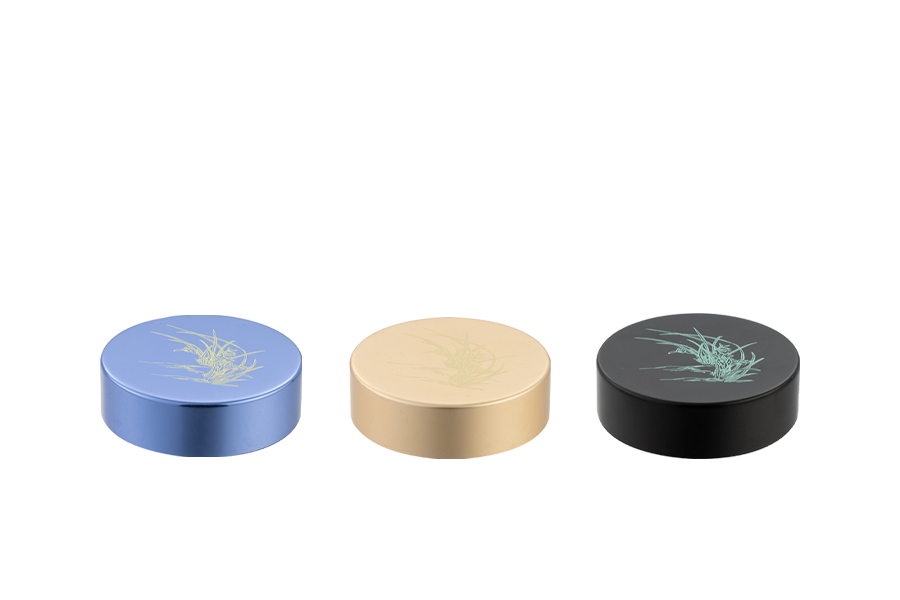

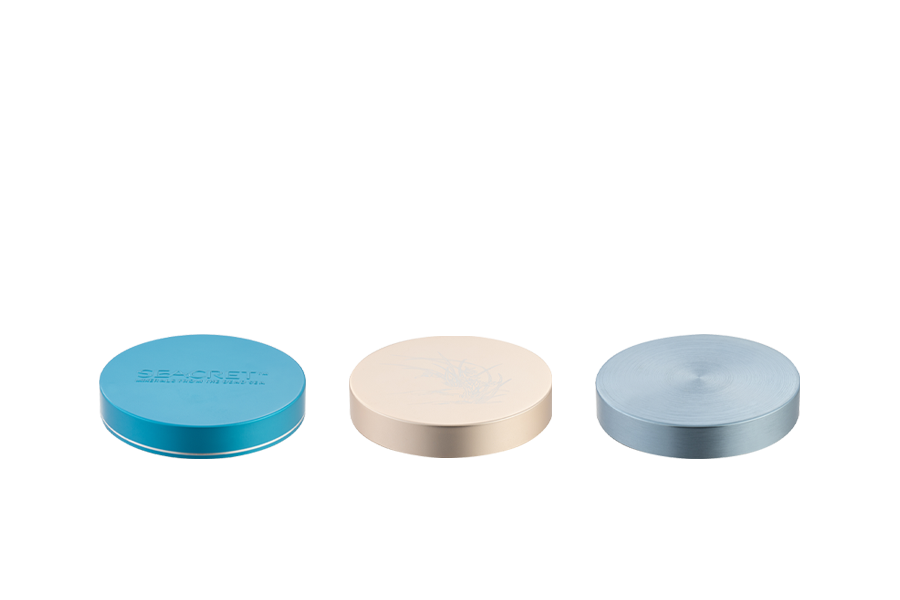

The aluminum bottle body is matched with a screw cap and a vacuum pressing structure, reflecting the high-end texture from material selection to process details. The matte metallic luster and smooth bottle body lines fit the aesthetics of luxury packaging, while the damping feedback and silent design of the vacuum pump head when pressing further enhance the sense of ritual of use.

The vacuum bottle adopts a spring-free mechanical structure. The pump head uses a silicone sealing ring and a piston to achieve vacuum suction. There is no direct contact between metal parts and the contents throughout the process, which fundamentally avoids the risk of metal ion precipitation caused by traditional spring pump heads. This feature makes it the preferred packaging for people with sensitive skin, acne skin or fragile skin after medical beauty, especially suitable for "three-no" formula products without alcohol, fragrance and preservatives, such as medical cold compress gel and postoperative repair milk.

简体中文

简体中文 English

English