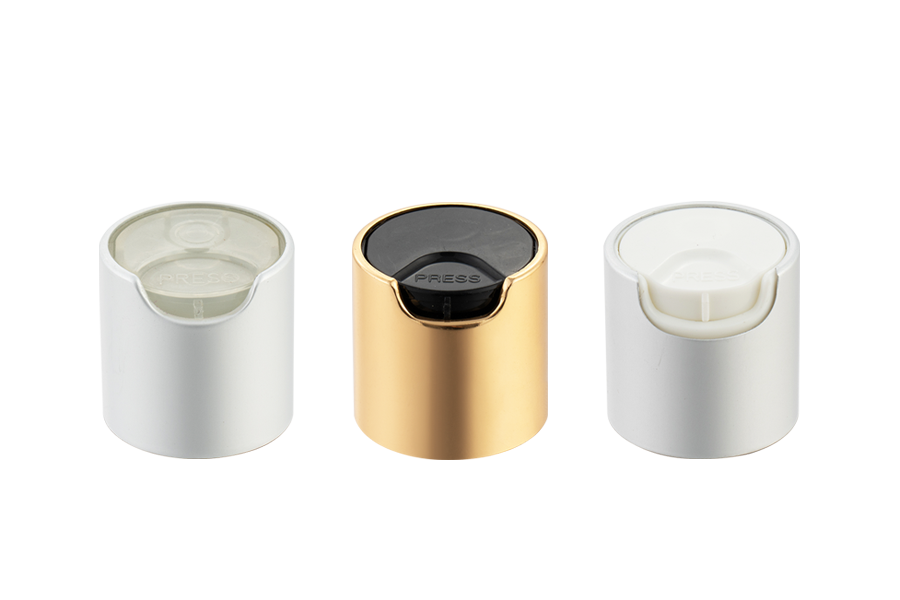

In the modern pharmaceutical packaging field, the choice of bottle cap is crucial, directly affecting drug quality and safety. Among numerous cap solutions, Aluminum Plastic Press Cap hold a significant position due to their superior overall performance.

Content

Aluminum Plastic Press Cap: A perfect combination of "metal" and "polymer material"

As the name suggests, Aluminum Plastic Press Cap are composite sealing components. Their core appeal lies in the ingenious combination of two materials with different properties to achieve functions that are difficult to achieve with a single material.

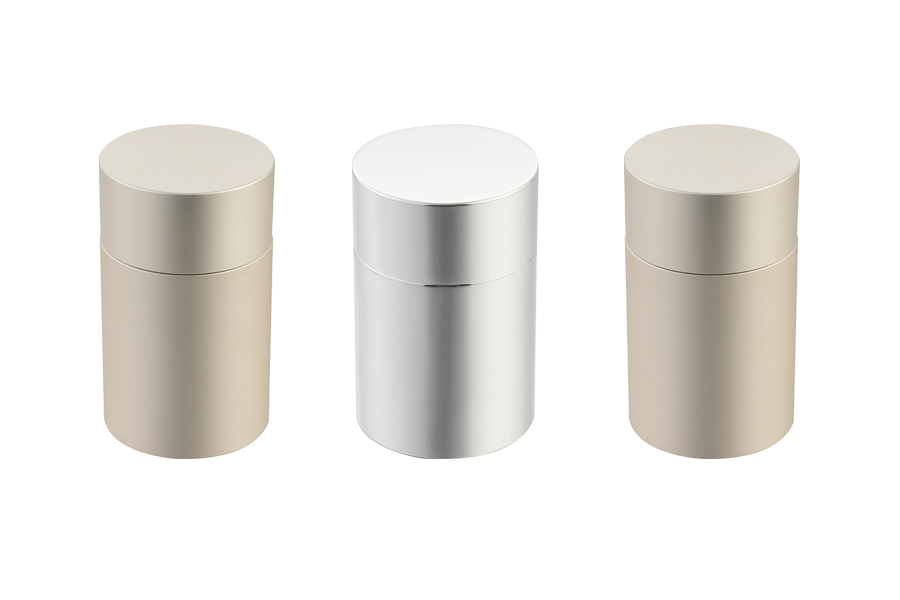

1. "Aluminum": Constructing a robust protective barrier

The "aluminum" in Aluminum Plastic Press Cap usually refers to the outer aluminum material or aluminum foil.

Main functions: The aluminum layer provides excellent barrier properties and mechanical strength. It effectively blocks the intrusion of external water vapor and oxygen, and also provides some light shielding, serving as the first line of defense for ensuring the expiration date of medicines.

The rigidity of this metal ensures that Aluminum Plastic Press Cap are not easily deformed during transportation and storage, maintaining good dimensional stability.

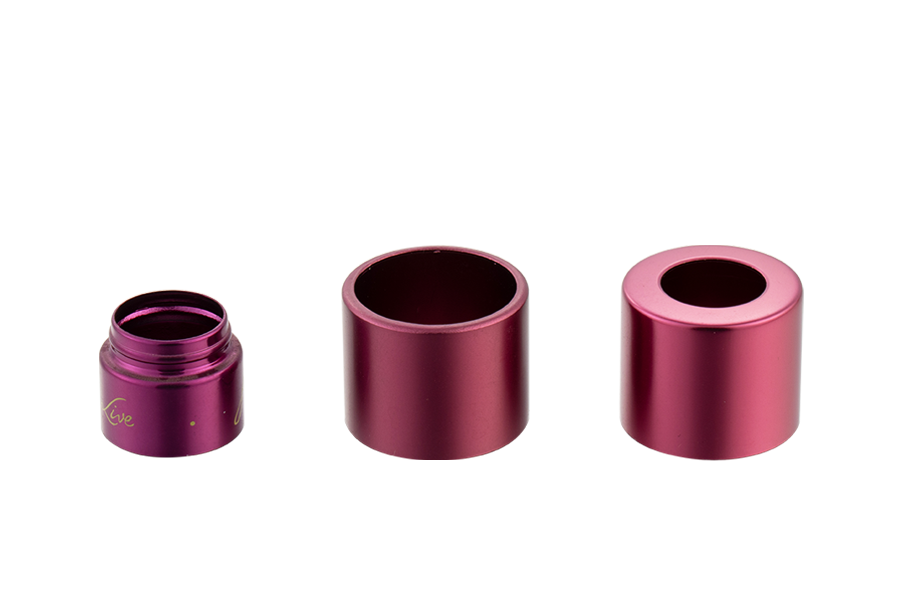

2. "Plastic": Achieving Reliable Inner Sealing

The "plastic" in Aluminum Plastic Press Cap refers to the polymer material of the inner layer, which comes into direct contact with the bottle neck. Common materials include polyethylene (PE) and polypropylene (PP).

Main Function: The "plastic" layer is key to achieving high sealing performance. It perfectly conforms to the edge of the vial or medicine bottle neck, providing excellent chemical compatibility and flexibility, ensuring a strong, leak-proof seal after compression.

The choice of plastic liner directly determines the corrosion resistance and chemical inertness of the aluminum-plastic cap for specific drugs, a core indicator of the quality of pharmaceutical packaging.

Structural Advantages Determine the Wide Application of Aluminum Plastic Press Cap

It is this "aluminum + plastic" composite structure that gives Aluminum Plastic Press Cap performance superior to traditional bottle caps:

- Improved Sealing: The aluminum provides external support, and the plastic provides internal elasticity; together, they achieve a completely leak-proof seal.

- Easy to open and spring back: Compared to pure aluminum caps, aluminum-plastic compression caps require less torque to open and feature a convenient tear-off design while maintaining good resilience.

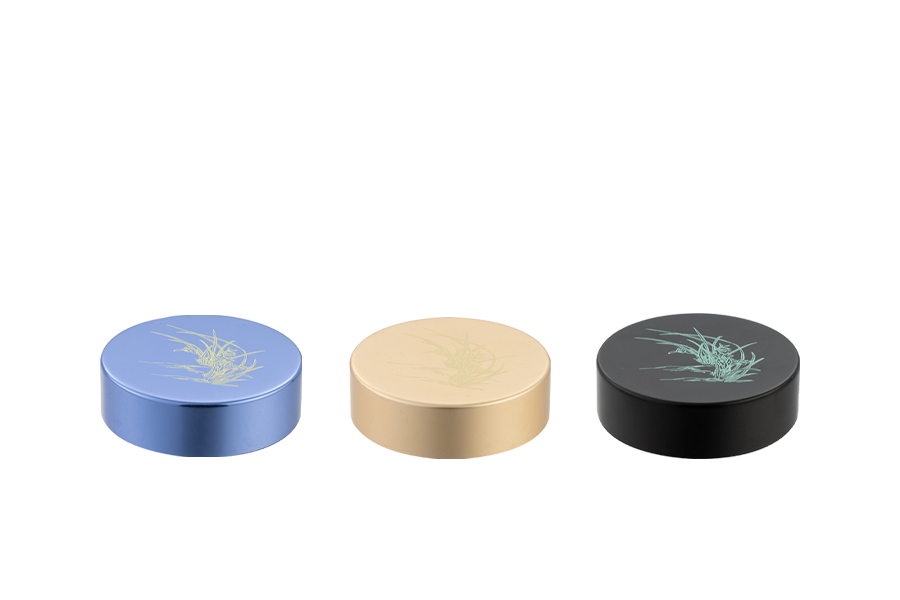

- Multi-functional integration: The outer aluminum layer can be easily color-printed and customized to meet brand identification and anti-counterfeiting requirements.

For pharmaceutical companies, choosing high-quality aluminum-plastic compression caps is crucial for ensuring product quality and enhancing user experience. Understanding the respective functions of aluminum and plastic helps us assess the technical capabilities of suppliers and the reliability of their sealing solutions.

简体中文

简体中文 English

English