As a common packaging form for liquid products, the material selection of spray bottles directly affects the storage stability, user experience, brand image and environmental performance of the product. At present, the mainstream spray bottle materials on the market include aluminum, plastic (such as PET, PP, PE) and glass, and Aluminum Spray Bottle have shown significant advantages in multiple dimensions due to their unique material properties.

The following is a detailed comparison of the differences between Aluminum Spray Bottle and plastic and glass spray bottles from 6 core dimensions, and analyzes their applicable scenarios and market value.

1. Lightness and durability

Advantages of Aluminum Spray Bottle

Lightweight: Aluminum has a lower density and is lighter than glass (2.5-3.0g/cm³). At the same time, it is stronger than ordinary plastics (such as PET, PP), easy to carry and not easy to deform.

Strong pressure resistance: Aluminum has high mechanical strength, can withstand the high-pressure spraying requirements of aerosols, and is not easy to burst or leak.

Shock resistance: Compared with glass bottles, aluminum bottles are not easy to break during transportation or falling, reducing the loss rate.

Disadvantages of plastic bottles

Ordinary plastics (such as PET) are easily deformed when exposed to high temperatures or long-term pressure, affecting the sealing and spraying effect.

Some thin-walled plastic bottles may be squeezed during transportation, causing the bottle body to dent or the nozzle to be damaged.

Disadvantages of glass bottles

They are heavy and increase logistics costs (especially cross-border transportation).

They are prone to breakage and are not suitable for outdoor, travel or sports use.

Examples of applicable scenarios:

Aluminum bottles: travel-sized perfumes, sunscreen sprays, sports sprays (need to be light and shatterproof).

Plastic bottles: low-cost daily chemical products (such as household cleaners).

Glass bottles: high-end perfumes (emphasis on texture, but need to be stored carefully).

2. Sealing and preservation of contents

Advantages of Aluminum Spray Bottle

100% barrier properties: Aluminum itself is opaque and oxygen-impermeable. When combined with an inner coating (such as epoxy resin), it can completely isolate ultraviolet rays, oxygen and moisture, greatly extending the shelf life of easily oxidized products (such as vitamin C essence, essential oils).

Anti-volatile: Compared with plastic bottles, aluminum bottles can effectively reduce the loss of volatile components such as alcohol and fragrances.

Strong airtightness: The combination of screw cap + aluminum bottle body ensures long-term sealing and prevents leakage.

Disadvantages of plastic bottles

Some plastics (such as HDPE and PET) are slightly permeable, and long-term storage may cause oxidation of the contents or loss of water.

Some organic solvents (such as alcohol-containing cosmetics) may penetrate plastic, causing the bottle to become brittle or deformed.

Disadvantages of glass bottles

Although glass itself has excellent barrier properties, the bottle cap usually relies on plastic or rubber parts, which may age and leak after long-term use.

Examples of applicable products:

Aluminum bottles: medical sprays, high-end skin care products, fragrances (need to be kept fresh for a long time).

Plastic bottles: short-term cleaning agents, low-concentration cosmetics.

Glass bottles: high-concentration essences (but need to be matched with high-quality bottle caps).

3. Environmental protection and sustainability

Environmental advantages of Aluminum Spray Bottle

Unlimited recyclability: Aluminum can be 100% recycled without quality degradation, and the recycling rate is as high as 90% (far exceeding the 20-30% of plastic).

Low-carbon production: The energy consumption of recycled aluminum is only 5% of that of primary aluminum, which greatly reduces the carbon footprint.

No microplastic pollution: Avoid the long-term harm to the environment after the degradation of plastic bottles.

Environmental issues of plastic bottles

Only some plastics (such as PET and HDPE) are recyclable, and the quality decreases after recycling (downgrade recycling).

A large amount of plastic packaging eventually enters landfills or oceans, forming microplastic pollution.

Environmental limitations of glass bottles

Recyclable but heavy, high carbon emissions during transportation.

Recycling and smelting consume a lot of energy (requires high temperatures above 1400°C).

Market trends:

The EU, North America and other markets impose taxes on disposable plastics, promoting the replacement of aluminum packaging.

Brands can use aluminum bottles to enhance their "green image" and attract environmentally friendly consumers.

4. Chemical stability and safety

Safety of Aluminum Spray Bottle

Corrosion resistance: The inner coating can isolate the aluminum from the contents and is suitable for products with a wide pH range (such as acidic lotions and alkaline cleaners).

No dissolution risk: Unlike some plastics (such as PVC), which may release plasticizers (phthalates).

Potential risks of plastic bottles

LDPE, PET, etc. may be corroded by solvents such as essential oils and alcohol, causing the bottle to mist or the components to migrate.

Some recycled plastics may contain impurities and are not suitable for pharmaceutical or food-grade products.

Precautions for glass bottles

Glass itself is stable, but alkaline liquids (such as high pH cleaners) may corrode soda-lime glass.

Regulatory requirements:

Aluminum bottles comply with FDA, EU 10/2011 and other food and drug contact material standards.

5. Appearance design and brand value

The appearance advantage of Aluminum Spray Bottle

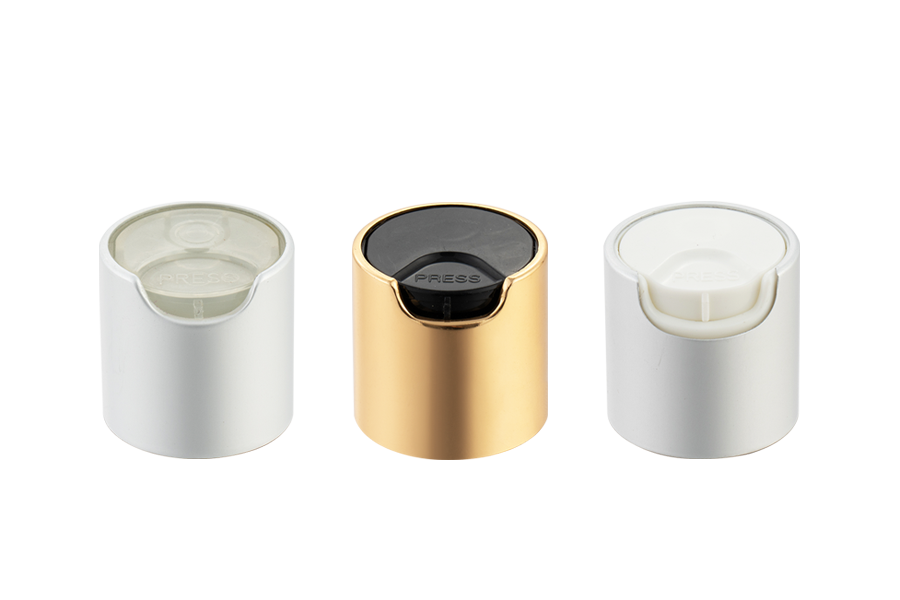

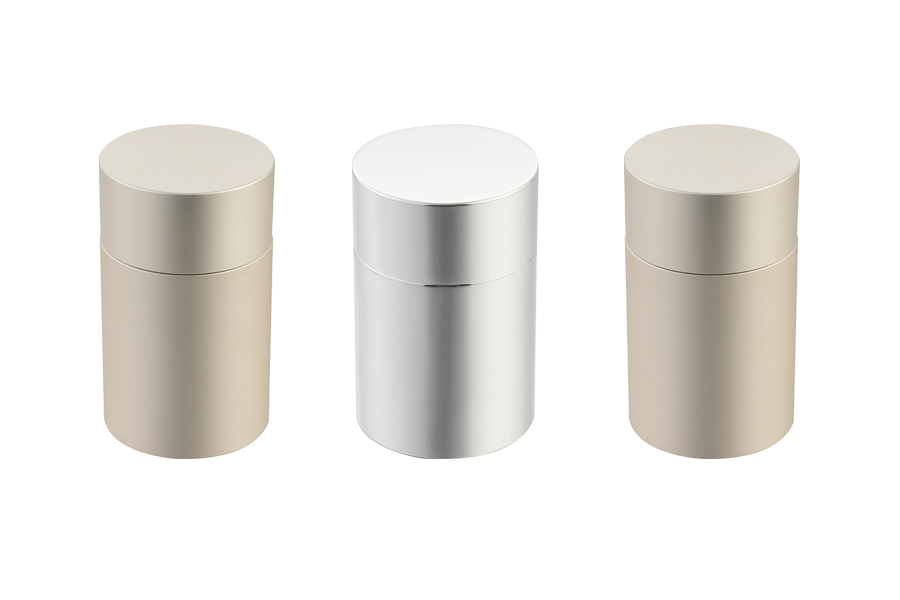

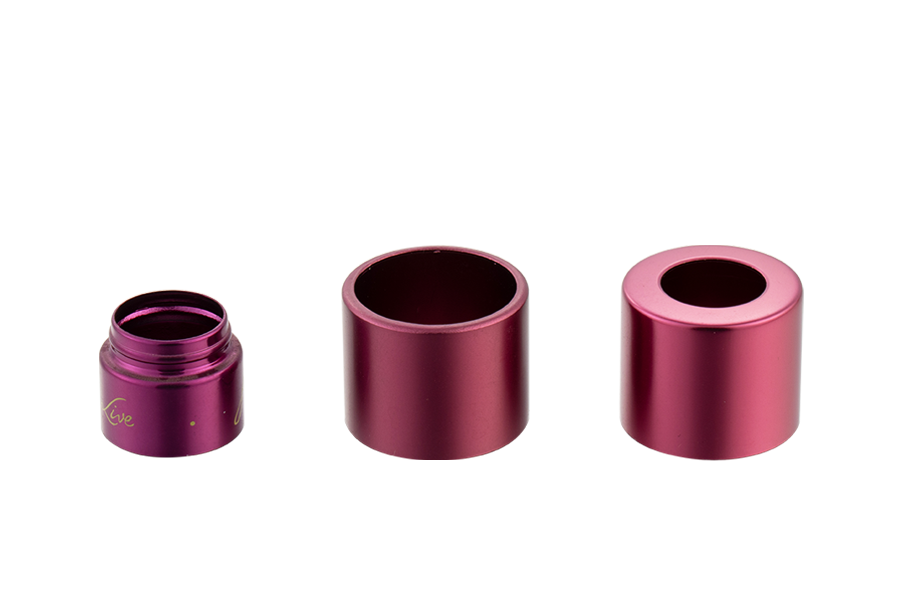

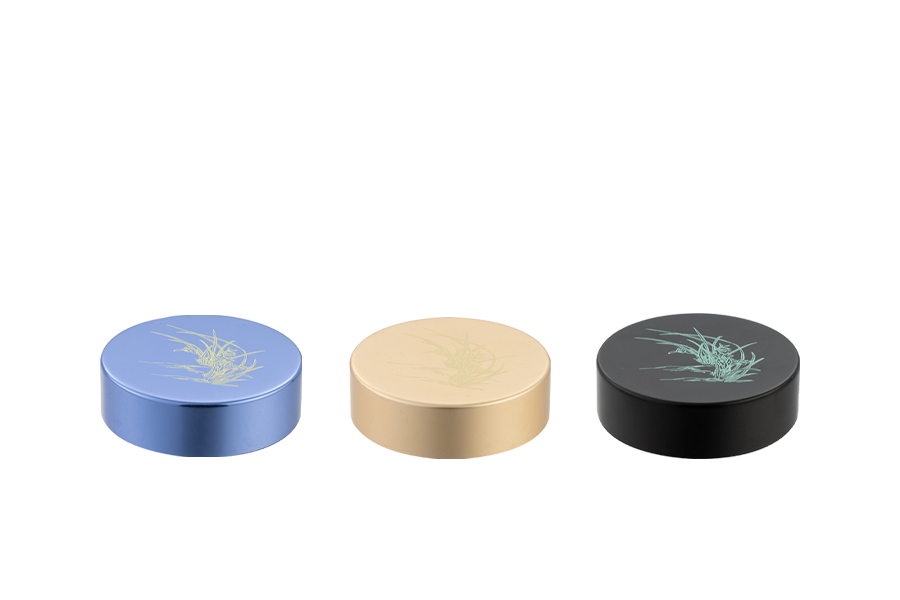

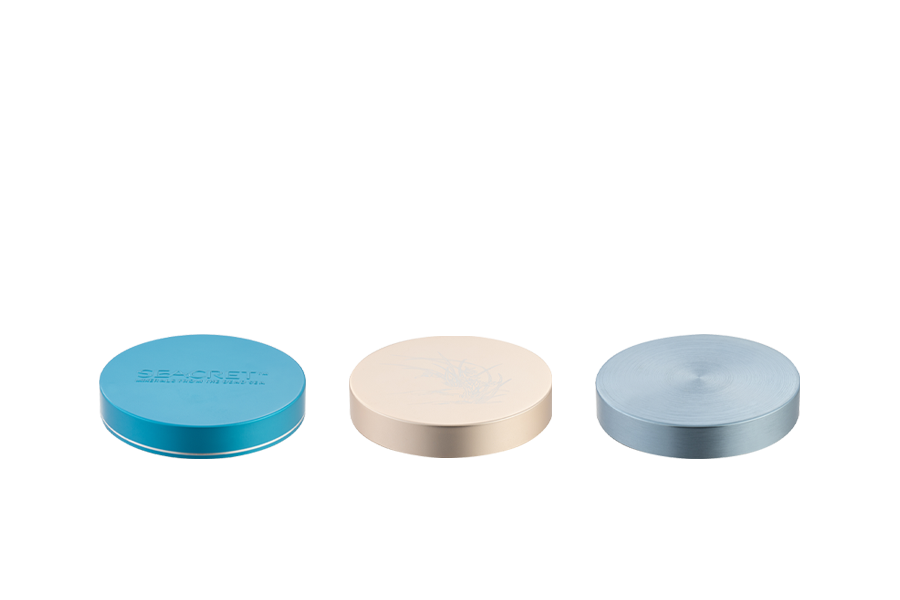

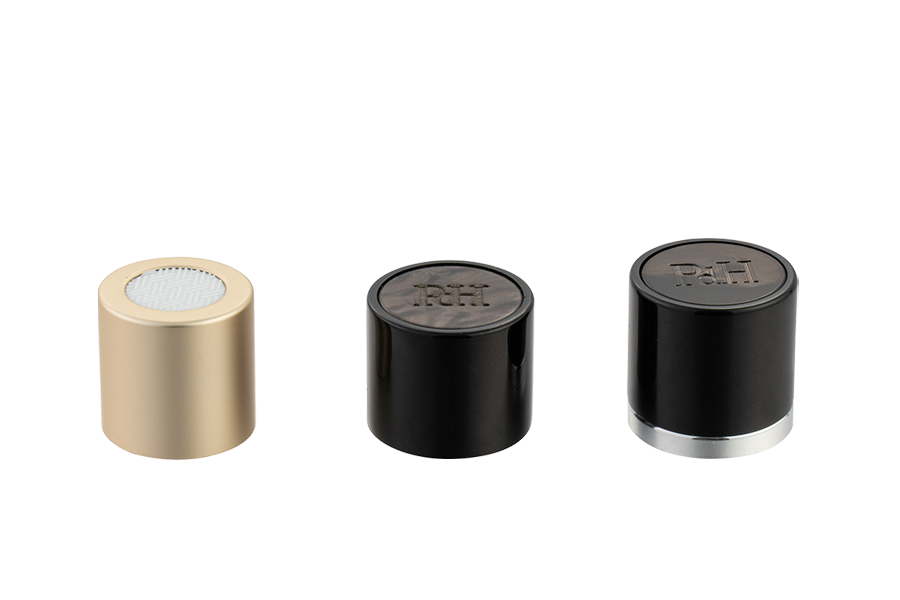

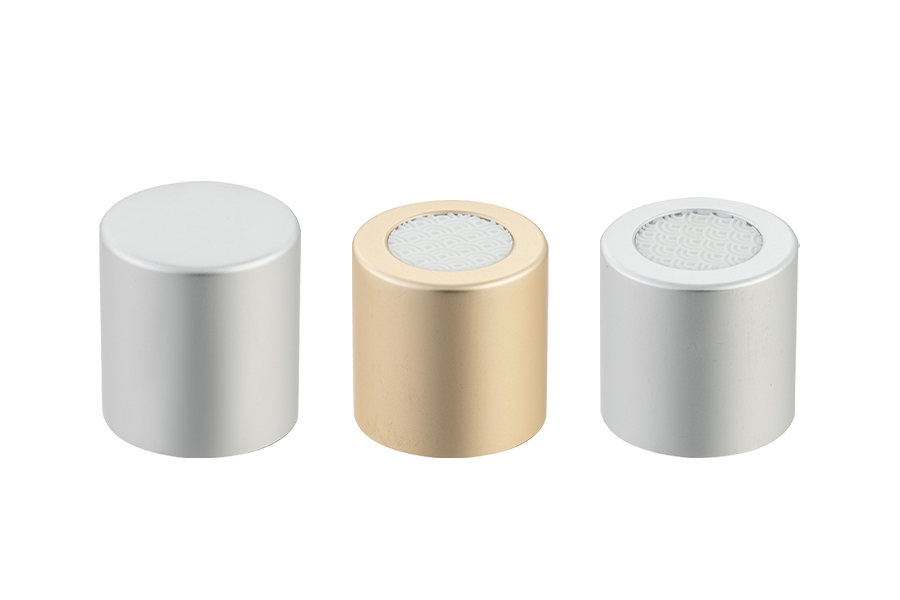

High-end metal texture: can be improved through anodizing, wire drawing, laser engraving and other processes, suitable for luxury packaging.

Flexible customization: support color printing, hot stamping, embossed logo and other designs to enhance brand recognition.

Limitations of plastic bottles

Strong sense of cheapness, low acceptance in the high-end market.

Transparent plastics are easy to look old due to discoloration of the contents.

Limitations of glass bottles

Limited shape (high mold cost), and heavy weight increases packaging costs.

简体中文

简体中文 English

English