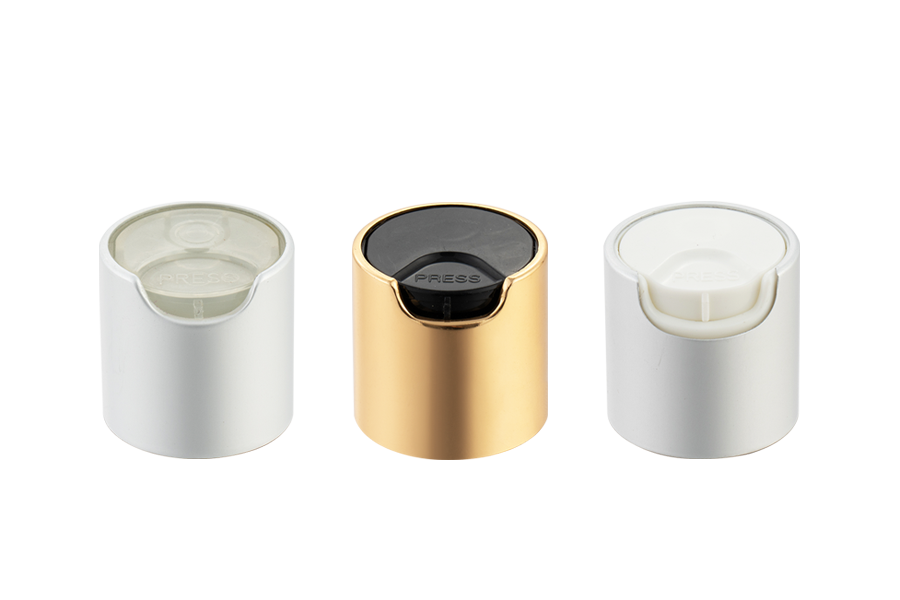

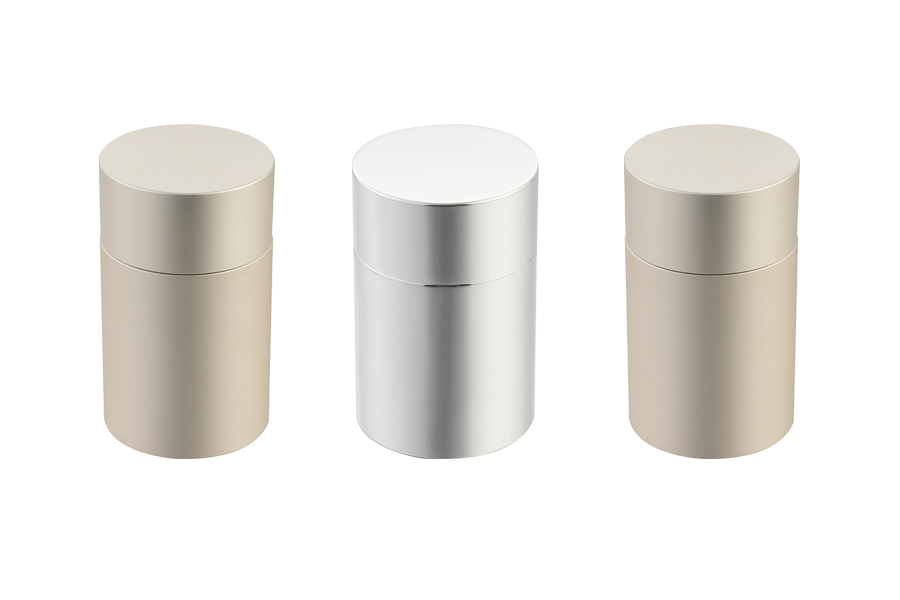

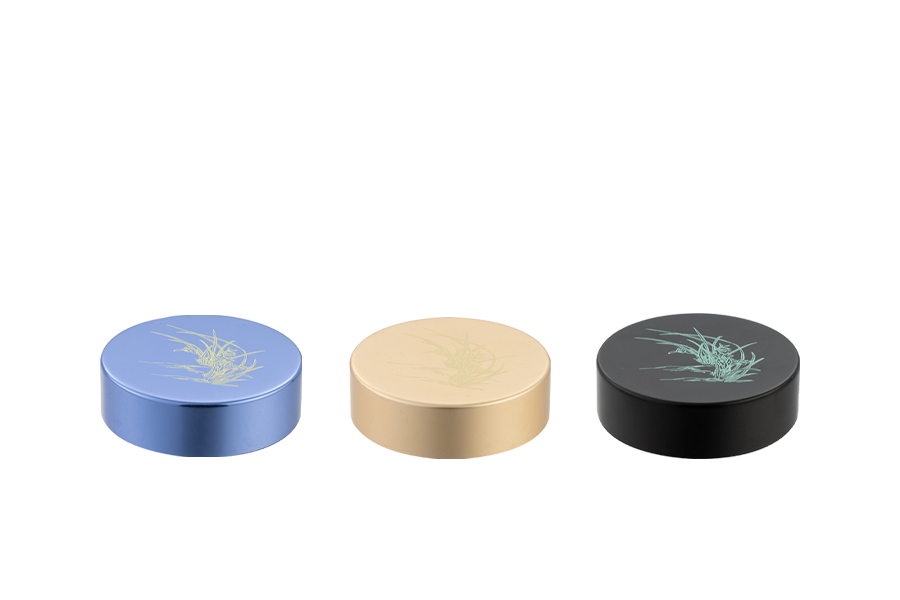

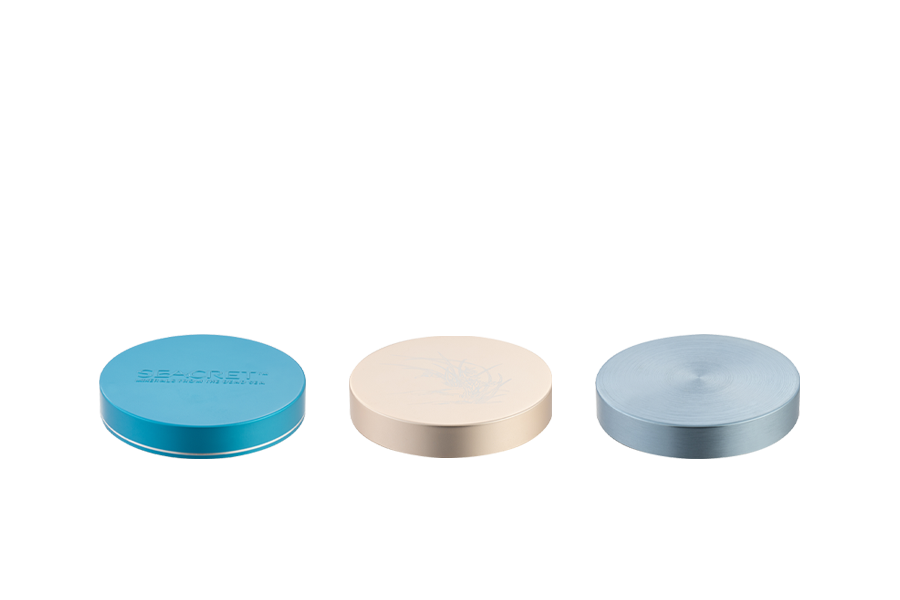

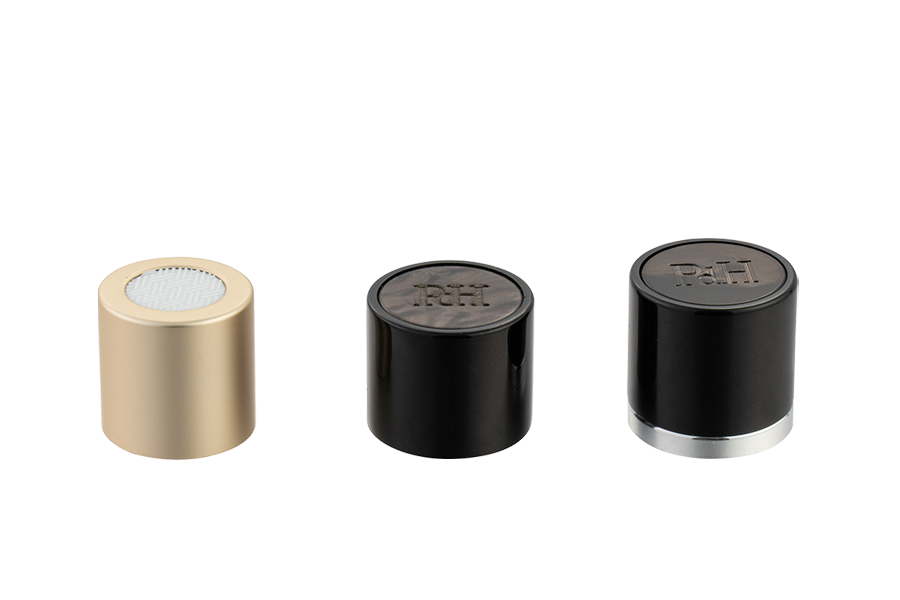

The soul of perfume lies in its unique and long-lasting fragrance. For any perfume, preventing fragrance evaporation is crucial, and the airtight design of the perfume bottle opening relies entirely on the sealing performance of the cap. In recent years, Aluminum Plastic Fragrance Lids have gained market favor due to their combination of the aesthetics of metal and the practicality of plastic.

Content

The Key to Sealing: The Core "Liner" and Structural Design

The secret to the high airtightness of Aluminum Plastic Fragrance Lids lies not in the outer aluminum material, but in its crucial internal plastic liner and precise structural design.

1. Core Sealing Component: Polymer Liner

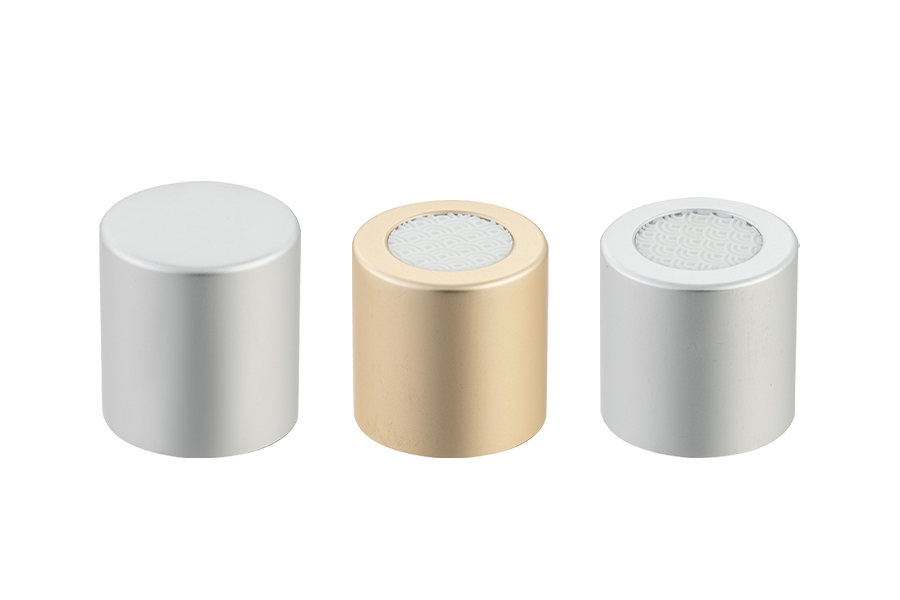

While the aesthetic appeal of the Aluminum Plastic Fragrance Lid is provided by the aluminum material, the actual sealing task is undertaken by the plastic liner made of polymer materials (such as PP or PE).

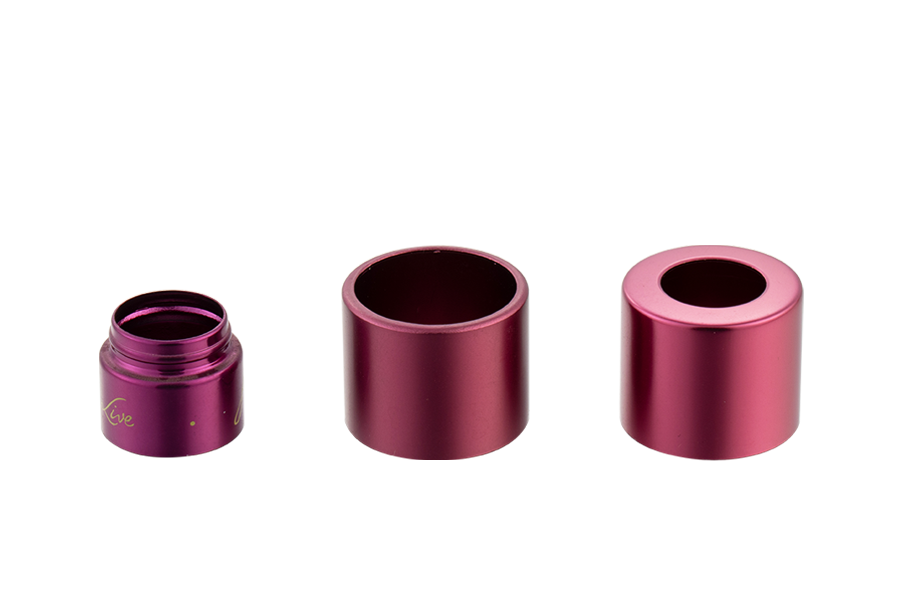

Inner Stopper/Sealing Ring: The bottom of the liner usually features a ring-shaped raised structure, which we call the sealing ring or inner stopper. When the cap is screwed on or pressed down, this sealing ring fits tightly against or inserts into the inner edge of the perfume bottle opening.

Elastic Deformation: This polymer material possesses a certain degree of elasticity and flexibility. When a locking force is applied, the sealing ring undergoes slight elastic deformation, filling the tiny gap between the bottle opening and the cap, thus forming a physically tight barrier layer. This is a key mechanism to prevent perfume evaporation.

2. Airtightness Guarantee: Snap-on and Inverted Structure

Modern Aluminum Plastic Fragrance Lids feature a multi-layered sealing system. Besides relying on material elasticity, structural design is also extremely important:

Snap-on Mechanism: For many non-screw-top perfumes, the Aluminum Plastic Fragrance Lid has a precise snap-on mechanism inside. This ensures that when the cap is closed, a constant and even vertical pressure is applied, causing the liner to press tightly against the bottle opening, achieving optimal perfume packaging sealing.

Inverted Structure: Some high-end designs employ an inverted structure, where the inverted mechanism inside the cap tightly interlocks with the corresponding structure on the outside of the bottle opening. This design effectively prevents the cap from accidentally loosening, further maintaining the airtightness of the perfume bottle.

Why choose an aluminum-plastic cap instead of a pure metal cap?

Aluminum Plastic Fragrance Lids, with their composite structure, demonstrate significant advantages in modern perfume packaging, especially compared to traditional pure metal caps. These advantages are mainly reflected in four aspects: sealing performance, lightweight, cost, and production efficiency:

Sealing Performance (Airtightness)

Aluminum Plastic Fragrance Lids are considered to have excellent sealing performance. This is mainly due to the plastic liner used inside. This polymer material has appropriate flexibility, allowing it to elastically deform when closed, thus forming a more stable and tighter sealing barrier layer. In contrast, while pure metal caps have good sealing performance, they are more susceptible to the deformation of the metal itself.

Lightweight

Aluminum Plastic Fragrance Lids have a significant advantage in terms of lightweight. By replacing some of the heavy metal materials with a plastic liner, the overall weight is significantly reduced. This not only aligns with the environmentally friendly trends in modern packaging but also helps reduce the transportation costs of perfume products. Pure metal caps are typically much heavier.

Cost Control

Due to the use of an injection-molded plastic liner, the production cost of Aluminum Plastic Fragrance Lids is lower than that of pure metal caps. The complex processing costs of metal are generally higher than those of plastic injection molding, allowing aluminum-plastic caps to maintain a high-end appearance while offering better cost-effectiveness.

Production Efficiency

The composite process of Aluminum Plastic Fragrance Lids typically allows for faster production speeds. Compared to pure metal caps, which require more precision machining and post-processing, the manufacturing process of aluminum-plastic caps is more efficient.

In this way, Aluminum Plastic Fragrance Lids provide a more economical and lightweight packaging solution while ensuring the airtightness of the perfume bottle and effectively preventing perfume evaporation.

简体中文

简体中文 English

English